Every man who does housework should have a good screwdriver in his arsenal of tools. If not already, then be sure to plan your purchase. Our article will help you figure out how to choose a screwdriver for your home. It will be difficult to do without it when performing repairs, construction work or household chores, when it is worth hanging a cornice, assembling furniture or unscrewing old screws. From our article you will find out which screwdriver to choose that will fit your ideas. At the same time, you will be able to understand which option corresponds to the optimal combination of quality and price.

Content

- 1 Types of screwdrivers

- 2 Application of screwdrivers

- 3 Design features of screwdrivers

- 4 Choosing a screwdriver: professional advice

- 5 Screwdriver: professional or household

- 6 Budget drills

- 7 Battery type: features and characteristics

- 8 The main characteristics of batteries for screwdrivers

- 9 Battery types

- 10 Varieties of cartridges

- 11 Reverse move

- 12 Design solution and ease of use

- 13 Case equipment

- 14 Electromechanical properties of the device

- 15 Additional options for buying a screwdriver

- 16 List of manufacturers for screwdrivers: which brand to give preference

- 17 And finally

Types of screwdrivers

Very often, buyers understand this tool as several types that have common options, but also not without serious differences.

We will highlight the most important of them. These are 3 types: electric wrenches and screwdrivers, as well as drills and screwdrivers. Some models may be equipped with a shock function.

There is a high demand for a cordless screwdriver that works autonomously. But it is quite possible that it will be more convenient for you to work with a tool that is powered from a 220V network. This is a network type.

To understand what is better to choose, you need to familiarize yourself in more detail with each type. You will understand what kind of work the tool will allow to make, what loads it can handle.

Electric screwdrivers

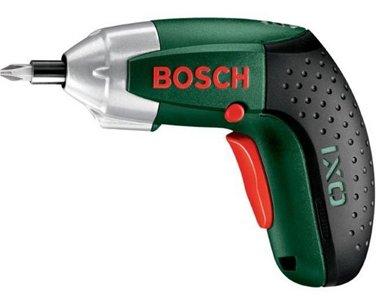

Let in terms of their operation indicators and the general degree of functionality, cordless screwdrivers are inferior to standard drills, they have special advantages that make this type of tool in demand among professionals, as well as amateurs who buy it for homework. These advantages include low weight, compact layout of the device, as well as high ergonomic properties. Due to this, screwdrivers with a battery structure can be used when the use of a more serious tool in size is not possible.

Electric screwdrivers are convenient to use if you need to carry out minor fixing manipulations. Such tools are useful for working on a production line where small household equipment, office equipment is produced. Craftsmen also use them to assemble furniture.

The tool is compact in size, meets the properties of ergonomics, and also does not weigh much. The screwdriver is easy to use, the craftsmen note that hand fatigue does not occur, and therefore it is comfortable to carry out tasks at a height with its help, for example, if you are installing suspended ceilings.

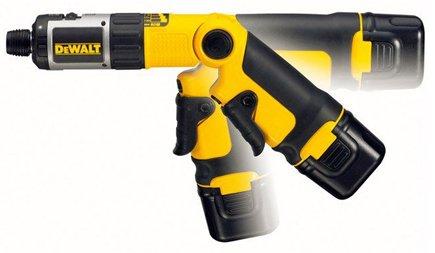

Cordless screwdrivers are available in different layouts. Many models have a cylindrical body that is equipped with a swivel joint. It will allow, if necessary, to fold the device, as well as to concentrate the downforce by hand. The picture shows this model for visual reference.

There are other pistol-shaped screwdrivers that are familiar to many. It is compact, comfortable and easy to fit in the palm of your hand.

On the market, you can find convenient models with a swivel joint, which is presented in a working head equipped with a rotating chuck. Due to this, it becomes possible to carry out work on tightening the fasteners or dismantling in inconvenient places where it is not possible to start a simple tool.

The compactness of power tools is due to the use of small batteries, which have a voltage of 3-9 V. Screwdrivers do not have a high rotation speed. This is 150-250 rpm in 1 minute. For their direct purpose, this is quite enough, as well as a tightening torque of about 10 N × m. for many fasteners, in particular in domestic conditions, this indicator will be quite sufficient and even in excess. In general, there are also perfect models that are equipped with a 2-speed switch. They can perform drilling work with wood and plastic. The rotation frequency can be up to 600 revolutions per minute.

Almost all cordless screwdrivers are equipped with a bit adapter with a 6-point ¼ ”shank. As a rule, bits for different types of fasteners are different, as are drills, which have a small diameter with a 6-point shank. They are included with the screwdriver itself.

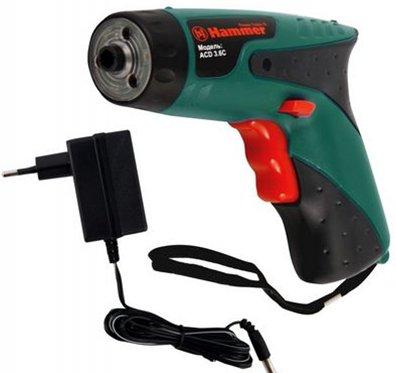

Unlike larger tools, electric screwdrivers are often equipped with a non-removable battery, which is located in the product body. A special power supply unit is used as charging. This is the adapter that connects to the network.

As a result, you will have an excellent tool at your disposal that will also allow you to mechanize the entire process of working with fasteners. A cordless screwdriver can be a great helper. In convenience, it is much more comfortable, but it is also inferior to the screwdriver in terms of functional features.

Wrench

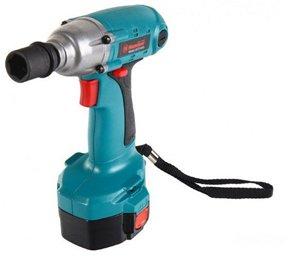

Another tool that looks like a screwdriver and can replace it in some cases is a wrench.

In the event that your work involves frequent operations with bolted connections, then you will not find a better option. When the master often resorts to the installation and dismantling of threaded connections of large or medium diameter, then he may limit himself to using wrenches. Those. this will affect labor productivity.

An example may be an assembly production put on stream, or what is found in private practice, auto repair shops, tire fitting. Moreover, when repairing cars, you can very often come across old corners that turn sour. It is not easy to unscrew them manually, even if processing is carried out due to a special composition. This is particularly difficult. As a result, the impact wrench must be used.

The design of the tool consists in the fact that, in addition to the rotational movement, impulse actions with a certain frequency are transmitted to the working area of the spindle with a special structure of the mechanism. Those. this is in some way micro-impacts that can move from the place or remove the nuts and bolts that are heavily rusted, which will not violate the integrity of the edges of the head.

Most impact wrenches come in a standard pistol grip pattern. But they can be used in conjunction with a special side handle to concentrate the downforce and push the joints.There are also devices of the "straight" type, which differ in the perpendicularly located working head, which is needed to perform operations in the area of hard-to-reach places.

Of course, such operations require high drive power. As a rule, it is in the range of 350 W for small instruments and can reach 1300 W for devices that are usually classified as professional. In this case, the speed of rotation will not matter much. It is not incredibly large, but due to this it is possible to achieve a high torque, which, even in the case of weak impact wrenches, will be 200 ÷ 300 N × m. You can compare it to the same cordless screwdriver that we reviewed today in the article.

In models of a professional level, where the power ratings of the electric drive are more than 1000 W, this indicator sometimes reaches 1000 N × m. It should be noted that at first glance, the impact wrench resembles a screwdriver. But there are also distinctive features. This could be the lack of a ring to adjust the maximum torque of the "ratchet". The working tip of the spindle is also different. Oftentimes, there will be a square adapter that fits the socket heads. The size of its power models differ. ¾ or 1 inch is inherent in professional-grade models, but ½ is in the household class. Those. sets of heads should be purchased appropriate, even if there are adapters of a special level for this case.

As a rule, impact wrenches are equipped with a square adapter that will fit the socket. Some firms provide for the creation of a special adapter, which can be attributed to universal devices. As a result, there will be a slot in the center of the spindle for inserting standard 6-tigers ¼ ". These can be drills, shank bits.

But even this fact is not able to make the tool 100% universal. It has a number of specific electromechanical properties that are tailored for a number of specific situations. This is both high torque and impulse mode. All this can be superfluous or harmful in the case of working with materials that do not need excessive efforts. The low rotational speed may not be sufficient for drilling.

Those. we can say that if the specifics of the master's activities provide for the frequent use of the tool, then the impact wrench will be an excellent addition to the screwdriver, but he cannot become a full replacement.

It is better to acquire such a versatile kit that will be useful in your work. By the way, quite a lot of popular brands produce such sets. They operate on one set of batteries. This is a truly universal offer, but there is also a disadvantage - an expensive price, and therefore the purchase should be planned and justified.

Drill Drivers

We present to your attention the most popular and frequently purchased type of instrument, which is also distinguished by increased properties of versatility. Many of these tools are designed according to the basic pistol look design.

The classic layout is shown in the picture above. Let's take a closer look at it in more detail. All elements will be discussed in order:

- The body is made on the basis of plastic with impact-resistant properties. Some models have an all-metal case, and therefore it is customary to refer them to the professional range. Inside there is an electric drive, which is crammed with control elements, as well as an air cooling system, thought out to the smallest detail.

- the pistol grip can be made with rubberized pads that will prevent the tool from slipping in the worker's hand. They contribute to the comfort of working with him;

- rechargeable battery with fixation of the mechanism in the handle.In many models, the view is as close as possible to what is shown in the picture. But keep in mind that a number of modern tools can be equipped with batteries with high power and compact size. They are hidden inside the handle device, which makes working with the screwdriver more convenient;

- the trigger is presented in the form of a key. Moving the trigger at the same time is able to adjust the rotational speed of the screwdriver spindle. As a rule, the trigger is covered with rubber or soft plastic;

- the spindle rotation direction switch is designed to make the process simple. Reverse is activated by pressing the finger;

- the gear switch makes it possible to change the modes of operation of the tool. The revolutions can be small when taking into account a large tightening force, or, on the contrary, they can be provided with high-speed rotation, which is needed for drilling. But keep in mind that this option is not present in every modern instrument model;

- clamping chuck. This can be a drill or bit holder. The design of the cartridge is presented in different solutions. Some models do not have a chuck, but they do have a 6-taper in. Socket that is matched to the shank of standard bits or special drills;

- the next element is chuck jaws with a clamping type;

- a torque limiting mechanism is a must in any tool design. As a rule, it is performed according to the "ratchet" principle. Those. if the set tightening torque is exceeded and the clutch slip with a characteristic sound. The number of positions for setting the moment can be from 5 ÷ 6, but in professional ones it reaches 20 pieces. As a rule, a drilling mode is provided, when rotation is transmitted from the gearbox to the chuck area, without any torque restrictions. This mode is indicated in the form of a corresponding pictogram;

- LED illumination system for the work area. Modern models of screwdrivers are often equipped with an LED illumination system for the working area. Its location can be different.

Those. this type of screwdriver is universal, which makes it possible for it to be popular with professionals and home-level craftsmen.

Application of screwdrivers

The tool is actively involved in work on suburban areas, as well as apartments. Whatever tasks for repair or construction have been set, it is difficult to do without it. Any home craftsman who relies on his own skills and powers will not argue about this. And professional builders in the arsenal of tools contain a screwdriver. Due to it, it is convenient to fix plasterboard sheets during finishing work, and it is not possible to assemble furniture without this tool.

A screwdriver is used to screw in or unscrew the fasteners. These are bolts, screws, screws and screwdrivers. In the case of installation, you can fix anchors and dowels with it. Both soft and hard wood lends itself to drilling.

With a screwdriver, you can thread metal parts and even in sheets. In general, the tool is really irreplaceable in practice.

Design features of screwdrivers

Let's explore what elements make up a screwdriver. It:

- an electric type motor that rotates at a certain speed;

- a planetary gearbox that transfers the force to the spindle area. It has a clamping chuck;

- a clutch is attached to the gearbox, which contributes to the regulation of the torque;

- in order to fix the nozzles on the shaft, they are bits, there is a special cartridge;

- the control system is represented by the "start" button, as well as a switch with a reverse motion;

- the power supply assumes the use of a battery. For this reason, the tool is indispensable if there is no outlet nearby or there is no long cord at hand.

Choosing a screwdriver: professional advice

Take into account that different variations of screwdrivers will be presented on store shelves. Paying attention only to the cost is not worth it. Carefully read the passports of those models that you think are appropriate for the purchase.

They will indicate the technical characteristics of the device, which are important. These are rotational speed, torque and battery type, if any. In accordance with this set of parameters, you need to choose the right tool for the job.

Screwdriver: professional or household

Think about what kind of renovation or construction work you plan to do. Based on this data, you need to determine the tool. If you are not a professional craftsman, it will be enough for you to get the device out of the case a couple of times a month, and therefore you should not spend money on a professional tool.

The amateur model is battery operated. It will be quite enough to cope with tasks in everyday life. She has an excellent functional set, less weight than a professional one.

If every day you need to collect, build or screw something, then you should not look towards cheap screwdrivers. Pay attention to powerful professional models. They will be mains powered as a rule. They have a lot of weight and dimensions. It makes sense to purchase such network tools for those who decide to work with the tool under heavy loads.

Budget drills

Choosing one or another tool, the owner needs to clearly understand what the purposes of using it will be in practice. Due to these preliminary sketches, you can evaluate which option you choose from those that are presented on the shelves in the respective stores.

Battery type: features and characteristics

Consideration is supposed to start with "energy". No matter how good a tool is, its performance will depend on batteries. Sometimes they cost like half of the whole set.

Most likely, many have come across a situation where the tool is working, but the power source is out of order. Indeed, it is accompanied by a number of new problems. It is not always possible to buy the very replacement that will be successful. Many manufacturers do not sell batteries on separate items. Probably, this is necessary to stimulate buyers to buy new tool kits.

The main characteristics of batteries for screwdrivers

It is worth noting here that it is worth paying attention to the capacity and voltage. The operation of the device itself will also depend on these indicators. Let's talk about this in more detail.

The power of the electric drive will depend on the voltage indicators. Those. maximum torque, which determines the functionality of the tool. The sale will include screwdrivers with a battery voltage of 9.6; 12; 18, 14.4V. True, this is not the limit for powerful professional devices. Sometimes, batteries can be 20 V, 36 V. In fact, for a household tool, 9 V is a small parameter. It is better to look at 14.4V. This is the "golden mean".

It may happen that you come across almost the same models of screwdrivers from the same brand, but after studying the technical parameters, you will understand that they have a difference. It will be related to the supply voltage. Those. the power indicator in question. In this case, it should be understood that the battery will not be interchangeable. The drive has properties for a specific voltage, and therefore cannot be exceeded. Otherwise, it is fraught with the failure of the instrument altogether.

The picture shows this option when the models of the screwdriver are similar, but they have a difference in the form of rechargeable batteries.

Battery capacity indicators are usually measured in Ah or Ah. You can find different designations. These are amperes hours.As a rule, the indicator will be presented on the marking, which is indicated on the battery case near the voltage.

Those. the battery capacity is a value that shows how long the tool can operate on one charged battery in full when no recharging is needed. Of course, the larger the value, the less often you need to stop work in order to replace the power supply and set the cells for recharging.

As a rule, for household screwdrivers that are used from time to time, a capacity indicator of 1.2 ÷ 2 Ah will be sufficient. It will not be possible to use this indicator intensively, and therefore it is better to pay attention to sets with a battery capacity of 2 ÷ 3 Ah.

Battery performance will directly depend on the type of battery. This issue should also be carefully considered.

Battery types

Nickel-cadmium batteries (Ni-Cd)

Due to their low cost, batteries remain the leaders in mass use in middle-class power tools. Despite the fact that they are replaced by batteries of the perfect level.

They are reliable, and even inexpensive. It is also convenient that operation and storage are possible at low temperatures.

It should also be noted that this type is the only one of all that is known today, which is not afraid of a full discharge. The battery can remain discharged in storage. It will turn on at full power after you charge.

There are drawbacks. They are connected with the fact that the battery is not capable of reaching high specific capacities. In the best case, it will be 2 Ah, but this is the marginal result. This option fails quickly enough. He cannot withstand more than 1000 cycles. It's about charging and discharging.

This type of battery is prone to self-discharge. This happens in the case of infrequent functioning. It seems that the charged battery has "sat down", and therefore cannot cope with the task at full capacity.

The main ailment of batteries is also that there is a "memory effect". You should not put it on charge if the resource has not been fully used. This is due to the fact that when receiving a charge not from "zero", the charge level will not be perceived by the device as a minimum value.

The capacity of a charged battery will spontaneously decrease by the amount of previously unused potential. You will need to discharge the battery in any of the ways. For example, connect a lamp or a flashlight, which usually comes with a screwdriver. Only then can it be inserted into the charger. This is not always convenient. For example, it seems that the power of the tool is insufficient, and therefore the hands themselves begin to reach for the battery for charging, but this can lead to breakdown.

Improper disposal of nickel cadmium batteries that have failed is a cause for concern. The thing is that a person harms the environment. We need to take care of our planet, because all this will negatively affect our children and the body as a whole in the future.

In fact, the nickel-cadmium battery is an excellent workhorse. They are most often installed on household class models. In such conditions, their qualities are quite sufficient.

Nickel metal hydride batteries (Ni-MH)

Here is an improved view of Ni-Cd developers. But it must be admitted that they did not manage to fully solve the problems with shortcomings. Let the option have many advantages, but nickel-metal hydride batteries could not get much distribution. Their advantages are that batteries do not harm the environment, including after disposal. The charge capacity is high. It may well reach 3 Ah. Combined with a more compact battery. Those. the power supply capacity is high and specific.

The memory effect is still there, but not so significant. On the negative side, keep in mind that this battery option is high for the price. The duration of the "active life" is short, the number of recharge cycles is not more than 500. Such batteries have a high level of self-charging, the drop reaches 10 percent in the first day of storage. Even if it's a full charge.

Battery performance is reduced when operating in freezing temperatures.

Do not store this type of battery in a discharged state. Those. the high cost per battery is not justified. It is better to buy a cheap running version - nickel-cadmium, or waste it on the next type of batteries, which we will talk about below

Lithium-ion batteries (Li-Ion)

Before you is a modern version of the battery, which involves the use with a stand-alone power tool. These are powerful and capacious batteries with considerable advantages.

The battery can be recharged at any level of discharge. There is almost no memory effect. Among other batteries, they have high rates of charge capacity, as well as power density.

There is a self-discharge effect, but it is extremely weak. Norm - for 1 year of storage under normal conditions, a lithium battery will lose 20 percent, but not more.

Service life is 3 times longer than that of analogues of other types.

As for the disadvantages, they lie in the high cost. This is a conditional drawback, because the performance properties are high, and therefore the purchase will pay off.

It is important to note that the operating temperature range is wide, and therefore the devices can be used in cold weather, but keep in mind that there will be a loss of performance. If the outside temperature is sub-zero, charging will not be accepted by the battery.

The battery must not be discharged to zero. It will not be able to charge again. The disadvantage is really significant. Manufacturers take it into account, and therefore the devices have special electronic circuits that simply do not allow full discharge. Moreover, it is a very common trend to equip batteries with charge level indicators to allow the user to monitor their charge.

When choosing a battery model, get a better set of 2 devices at once. Thus, you can ensure the continuity of large-scale work. While one battery is installed on the screwdriver, the second will go through the charging process. True, when using Ni-Cd, it is always worth keeping that a full discharge is necessary so that there is no "memory effect".

Often, a technical document from the manufacturer will indicate the average battery charge time. The smaller it is, the more convenient it will be to use the tool. Those users who do not want to mess with the battery, who are not afraid of the power cord pulled from the tool, we advise you to buy a network model.

The properties of the working plan will not be worse for this. This cord will simply affect the usability of the device. When choosing, pay attention to the length of the mains cable so that it is sufficient for the specific conditions of the application.

Varieties of cartridges

There are 2 types of chucks for clamping parts. It's about key and quick-release. For the first type, a special key is used, which refers to the gear type. If this is the second option, then the situation is simpler. The drill can be inserted as easily as the bit holder.

In turn, the chuck will have 1-2 couplings. It is controlled by a key. If the coupling is 1, then the device has an additional mechanism for locking the shaft when replacing one nozzle with another. In the case of 2 couplings, instead of locking, the chuck holds 1 of the available couplings, the second will clamp the chuck.

In a chuck with 2 couplings, when installing or removing tools, the lower part must be held by hand, and the upper part must be tightened or released.It is much easier to work with a single-seat one. The whole operation will be done with 1 hand. True, in this case, the screwdriver must have the option of locking the spindle. It can be automatic, triggered during installation, or forced. In the first case, it will turn on during rotation stop. But in the second - a special button is presented on the device.

Note that it is important when choosing a tool to clarify whether it has a forced spindle braking function. When the trigger is released, rotation should stop. Almost all modern models of screwdrivers are equipped with this option. But if you get hold of an outdated variation, then you don't need to buy a cartridge that rotates by inertia after turning off the power. Better to look for something else. The model will give its owner a lot of problems in further use.

Jaw chucks require the use of a key as described above. They are rarely used in the case of screwdrivers. The key will tend to constantly hit during operation, and the process of replacing the drill will take a lot of time and effort. But keep in mind that all the same, a lot of masters include this chuck in the package, and therefore, for drilling, which requires significant effort, the tightening force of the coupling chuck may not be enough.

In many cases, a simple jaw chuck that involves the use of a key can be useful. We advise you to opt for a model without a chuck, but with an adapter that has a ¼ ”hex.

In this case, if you need to tackle small drilling operations, you can use a small chuck that has an adapted hex shank.

Reverse move

The reverse helps to unscrew the screw if it is tight. Also useful when the drill gets stuck and is very difficult to pull out of hard material. As a rule, for this task, electronic switching of the motor poles is used. For convenience, the switch in the reverse mode is located next to the start button of the device. He has 2 positions, in the middle position between them, the device will be blocked. This is a necessary condition so as not to press the button at the wrong moment.

Design solution and ease of use

The parameter is really important. Don't just look at the color and appearance on the websites, you will need to go to the store to try on the tool. In the future, you will have to work with it, and therefore you need to pick it up and check how convenient it is. Try pushing the buttons to see if they switch perfectly. The center of gravity in this case will be in the area of the handle. If so, then you will not feel tired while working.

There must be a ring after the chuck to adjust the torque. When the screw is fully inserted, the device will not allow it to go deep at full force. Those. the rig won't wear out too quickly.

If you plan to assemble furniture, it is better to pay attention to small screwdrivers with low power, but the classic version of the tool will delight you with a large set of important options. For professionals, the option in the form of a whole combine is more appropriate, where there is an automatic feed function for self-tapping screws.

Case equipment

The contents of the instrument may vary. It is better if the case contains not only the device itself, but also additional attachments that will later be required in the work. This will allow you not to waste money on their purchase and your time in the future. Bolts, screws, screws have different heads. Nozzles will be required in the work, and there are a lot of them.

Electromechanical properties of the device

The possibility of a drive and a gearbox should be included in this category. We will talk about everything in order so as not to get confused.

So, in budget models, motors with a brush collector are used. This is an old and proven option. The solution is really reliable, but there are some drawbacks.The main one is that the friction forces are significant in the area where the brushes adhere to the collector lamellas. Of course, this is accompanied by a significant release of thermal energy, and the drive can quickly heat up. Moreover, sparking of the brushes in the collector area is not excluded. This applies to those situations when you need to work in conditions of high humidity.

Disadvantages can be eliminated with a brushless motor with electronic control. The absence of an additional friction area can lead to a sharp increase in the level of tool productivity. It was decided to test similar models that have the same properties of batteries. They have proven that a screwdriver that has a brushless motor can do 3 times more work than a brushed type.

A number of modern manufacturers have found it necessary to remove the motor housing, and therefore the units are located in the models in the screwdriver itself. We must admit that the decision is correct. We managed to achieve solid success in the total mass of the tool, the work became much more convenient. If it is possible to choose between a brushless and a simple drive, then we advise you to decide in favor of the first option. True, here you should rely on the availability of finances at your disposal.

When choosing, be sure to specify on the basis of what materials the screwdriver gearbox is made. This mechanical assembly will be subject to heavy loads. Quality is able to predetermine the optional capabilities and duration of the tool as a whole.

The metal gears of the planetary gearbox look preferable due to their durability and wear resistance. It should be noted that plastic gears are not of high quality. But still, their resource is less than that of high-quality metal options.

Deformation of one tooth on any of the gears will be fraught with complete destruction of the kinematic diagram of the gearbox, at best - jamming. Ie an undeniable advantage of metal gears.

The properties of the rotation speed of the working spindle will be presented in the device passport. No need to strive for high performance. For dismantling or mounting with fasteners, 500 revolutions per minute will be enough, but for drilling wood or metal 1200 ÷ 1500 rpm. Higher rates are also inherent in professional-grade instruments. They allow you to perform specific operations at the household level, but still you should not waste it, since many of the options will simply be useless for you in home use.

Adjustment of rotation speed from 0 to maximum values can be done by changing the effort to press the trigger. For comfortable performance of basic operations, choose a screwdriver that has the ability to switch the gearbox to low and high speeds. Usually, the switch is located at the top of the case.

Maximum torque is an equally important characteristic. The optional capability of the tool as a whole depends on it. To work only with small fasteners, 10 Nm will be enough, but this is most likely an electric screwdriver. In order for the tool to cope successfully with simple drilling operations, choose models with a maximum force, which have an indicator not lower than 25 Nm. Those. in the case when more is expected from the screwdriver, then you need to take 36 Nm or more. Under these conditions, you will cope with the task of drilling large diameter crowns in wood, and you will also work with metal.

Torque values for many consumers can be expressed in Newton meters. But they say little to the buyer. For this reason, manufacturers indicate additional and maximum drill diameters in the documentation for the tool, doing this separately. Those. for wood and metal processing. This will make it possible to make the choice much faster.

Torque control is present in almost all device models. As a rule, this is a ring that rotates, it has a scale on it. It indicates the minimum and maximum values that apply when drilling.

If the specified force is exceeded, the ratchet or slip clutch will operate. Those. excess torque will not be transferred to the fastener area itself.

The numbers on the scale will indicate the serial number of a particular switch position as the tightening torque increases, but note that they have no relationship with the diameter of the fastener, no matter how inexperienced users try to prove the opposite.

The drill symbol will indicate the torque that needs to be drilled.

Rotation direction switch is available on all models. If it is not available, the device will not function normally. Its usual location is indicated by a trigger, i.e. with the start key. In some miniature versions, it can be represented by 2 keys. This is reverse and forward rotation of the spindle.

Additional options for buying a screwdriver

A number of modern screwdriver models have useful options. They are also worth talking about, because when buying, you may be faced with the task of choosing them.

For example, there may be an impact force on the chuck of a screwdriver, except that there is a rotational one. This makes it possible to drill holes in some building materials. Such devices are equipped with a switch for shock and simple operation. It is located both on the tightening torque switching ring and can be taken out in a separate order.

The screwdriver can be with an impact function, which is equipped with an additional removable side handle, which accentuates the forward force when drilling is required. Buying such a model, you should really imagine that he can drill a brick wall or gas silicate, i.e. lightweight concrete. For example, if you need to drill holes in reinforced concrete structures in a panel-type house, it is better to have a hammer drill with you.

In operation, the pulse mode of operation of the device can be useful. Similar to the impact wrench analogy. This will allow you to cope with a sour type threaded connection or will accurately provide an opportunity to outline the drill entry into a material with increased density.

The activation of the pulse mode on the torque adjustment ring can also be present, or it can be performed as a separate button that can be pressed if necessary.

Additional convenience during work is the presence of a backlight, which is built into the device. This is an LED flashlight that can be in the area of the holder or on the axis of the device body. Experience shows that this is not always convenient. This is due to the fact that the cartridge shades the area of work.

The location of the lantern can be different. For example, the lower area of the pistol grip. The stream of light will be directed in this case so that the entire area below is illuminated for work. This gives additional comfort when working.

In fact, each scheme has certain convenience properties. You can evaluate them personally when you choose a tool. Don't be afraid to try it on in the store. Your comfort in the future will depend on this.

It is especially important to pay attention to such a criterion as the weight of the device. The instrument should fit comfortably in the palm of your hand and be balanced. If you plan to carry out work at a height, then pay attention to lightweight compact models. But for frequent drilling operations, the mass of tools will become a certain help in work. In each of the cases, when assessing the "throttle response" of a screwdriver in a store, it is worth evaluating how the center of gravity is located - it can shift backward or oppositely forward.

In each case, it is important that the hand does not get tired quickly, otherwise working with the device will not be comfortable and will become very tiring. The place that is more vulnerable will soon be covered with calluses.

Craftsmen who have extensive experience advise to inspect the place where the handle transitions to the trigger. It is better if it is smooth without having an acute angle. A transition of this type, like a rectangular one, is fraught with quick fatigue of the middle finger in the case of large-scale work.

Estimate the scope of delivery. So, the kit must necessarily include a charger with a power cord. The modern form of charging is presented in the form of an electronic circuit, which will not allow the battery to overheat, and it will automatically turn off when the upper charging limit is reached.

As noted above, buying a screwdriver that has only 1 battery is not the best solution. This is fraught with a number of inconveniences during work.

The complete set must also be represented by a flashlight. It will provide additional lighting during the work. Also useful is a device for completely discharging batteries with a nickel-cadmium structure.

Very often, the equipment is presented with various kinds of belts or holster-shaped covers, which allows you to conveniently place the tool on the master's belt when working at height. The holster is comfortable. It can accommodate the device and all accessories.

A set of bits and drills is not always to the taste of professionals. They believe that it is better to buy all the types that are required in the work, separately. However, manufacturers still supplement the complete set with drills that are of good quality. The specification is not always sufficient, and therefore it is still worth being prepared for additional costs if necessary.

Professional-grade screwdrivers can be optionally equipped with replaceable gear units. In addition to an adapter for 6-bit bits, a chuck with a quick-release device can also be installed on the tool. Moreover, the complete set can be represented by a gear attachment, which makes it possible to drill and tighten fasteners at an angle of 90 degrees. The replaceable nozzle is presented in the form of an eccentric, which transfers rotation to the drill or bit, provided it is displaced from the tool axis. The option is really very convenient. It allows you to get to those places where the body of a simple screwdriver does not fall.

But right there it is worth noting that the complete set is not cheap at the price. You should be prepared to waste.

List of manufacturers for screwdrivers: which brand to give preference

The main criterion for buying a quality screwdriver is considered to be the manufacturer's brand. It is also important to pay attention that in your region of the country there is a service department of the brand, where, if necessary, you could turn for help. Today, the KRÜGER brand, which represents Germany, has achieved great success. Users respond positively to its products, professionals agree with ordinary people that the tools are worthy of attention.

KRÜGER has developed 3 models of screwdrivers. These are 21.18 and 12V power ratings. The tools have different options and a rich set. The devices work for tightening, drilling, and at 21 V the model is equipped with an impact mode.

Professional cordless screwdrivers of the brand delight with excellent technical properties. They are powered by a high-capacity lithium-ion battery. It allows you to use the tool on a long-term basis. The 21 V drill has a built-in light that illuminates the work area. It can be used even at night if work is planned. It will also be useful in places with poor lighting.

Due to the tool, not only holes are drilled, but also fasteners can be unscrewed and screwed in. The cordless drill / driver is represented by a complete set, which includes a set of 13 bits and 7 drills.There is also a charger that will prepare the tool for work in 1 hour. On the plus side, there is also a reverse option. Due to it, you can get a stuck drill.

In fact, the Kruger tool is lightweight and compact. It can be available from any master. Due to the modification, prices for the "Kruger" will vary around 4-8,000 rubles.

There is no doubt that you can buy screwdrivers of another brand. Makita is a brand with an excellent reputation. Many professionals and simple craftsmen say that the screwdrivers of this brand are the best on the market.

The lineup is quite diverse. These are both inexpensive household options and professional offers. Due to the class of screwdrivers, the price will also vary.

Pay attention to the offers from the Bosch brand. The company pleases with high quality devices, reliable performance. Bosch has been known on the market for several years, and therefore you can enjoy good working conditions with the tool.

AEG brand screwdrivers are no less common. True, the cost of the tools is not cheap. Such products will only delight their owner, and therefore will be able to fully justify the finances spent.

DeWalt is a very good manufacturer that pleases with power tools. These are innovative developments in this area, which are always in demand among buyers, which speaks of the devices extremely positively. The lineup is wide, prices are different. Everyone will find a model of the right tool within their pocket.

Metabo screwdrivers are mainly equipped with electronics. The presence of a torque value that is adjustable in accordance with the needs of the owner during work is also encouraging.

Hilti tools are highly functional. But keep in mind that the manufacturer has unjustifiably raised prices, even if the warranty obligations are very tempting. Those variants of tools which are released by the brands "Sparky", "Hitachi", "Skil" are also in great demand.

There are also decent offers on the market of domestic producers. Pay attention to the Interskol and Zubr and Caliber brand screwdrivers. It is likely that you will note that their technical characteristics in some points will be weaker than their counterparts from other countries, but there are advantages here. The service center will be in our country, and the price level is acceptable. Moreover, many buyers of domestic products note that the tools are highly reliable, which is a big plus.

We do not advise you to buy products from Asian brands that have not been heard before. This purchase is a lottery. Someone is lucky, someone has to fork out for another purchase, since you are unlikely to receive guarantees from the manufacturer.

And finally

In our article, important parameters were set out that you should write out on a leaf and go with them to the store in order to find a decent tool that meets your needs.

For a household tool, the torque should be no less than 10 Newtons per meter, but the revolutions per minute are equal to 400-500. Be sure to pay attention to the presence of the reverse option, choose a battery device, better - nickel-cadmium or nickel-metal hydride type. Rely also on a voltage of 10-14.4 V, and also check that the screwdriver works for drilling and twisting.