Today there are many different roofing materials intended for the construction of the roof of a house, a summer residence, hangars and many other structures. This list includes the best corrugated board in 2020, which has excellent indicators of reliability, quality and benefits. Moreover, this material has a classic design that does not go out of fashion and perfectly suits most facades.

Many are interested in the question of which corrugated board is the best. This is due to the fact that quite often there are low-quality fakes, which after 2-3 years lose their properties and begin to deteriorate. In order to avoid this problem, it is recommended that you familiarize yourself with the general characteristics of this material, recommendations for choosing, as well as the highest quality models in 2020.

Content

The main features of corrugated board

Some people are interested in what is better: metal or corrugated board. Each of them is the best at something. Therefore, it is worth familiarizing yourself with the main advantages of the material and concluding whether it is right for you. The first step is to disassemble the procedure for manufacturing corrugated board. The product is made of galvanized steel by cold rolling. After that, a protective coating is applied to the surface.

With the help of profiling, the sheets are given various shapes. The best corrugated roof sheeting can be wavy, trapezoidal or U-shaped. It should be noted that, depending on the type chosen, not only the aesthetic component changes. The types also differ in strength and reliability.

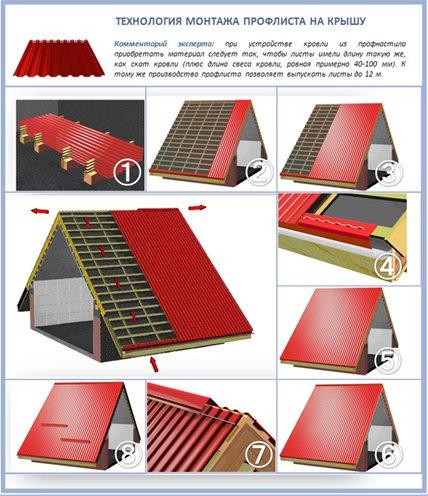

Another advantage is the absence of an unpleasant odor from the product. The fact is that many modern roofing materials have a specific smell that is not to the liking of many buyers, while corrugated board does not have such properties. In addition, the products in question are easy to cut and simply assembled. Suitable for installation are any roofs with a slope greater than 8 degrees and a slope less than 20 meters.

In terms of weight, it is the lightest roofing material on the market. This is a rather important aspect, since it greatly facilitates the installation process. With lightweight sheets, it is much easier to shape the roof. If these advantages are enough to purchase this material, then you can move on to the question of which decking are good for the home.

Classification of corrugated board

It's time to consider the main types of corrugated board. This will help you understand which corrugated board is better for the fence, and which corrugated board is better for the roof. All products are classified according to several aspects, namely:

- Marking;

- Production technology;

- Coating quality.

We propose to analyze each option in more detail.

Profiled sheeting marking

The marking of the corrugated board depends on the height of the corrugation. This figure varies between 1 - 14 centimeters. In this case, 3 types can be distinguished:

- Class C. This is a facade corrugated board, which is intended for the construction of fences and walls;

- Class H. Bearing corrugated board required for wall cladding, as well as for the construction of partitions;

- HC class.Roofing option suitable for roof construction.

Today, the most common markings include H45, H75, H114, C10, C20, C35. Each marking must be accompanied by the inscription “GOST”. If not, then the product was manufactured according to different standards. In this case, it is worth more carefully assessing the quality of the material.

There are additional markings for corrugated board. Thus, the letters “A” and “B” indicate the presence of painted sides. And the “R” marking confirms the presence of a capillary groove on the product.

Production technology

In 2020, there are 4 main technologies for the production of corrugated board. Each organization tries to stick to its own algorithms:

- Aluminized sheet steel;

- Rolled products with aluminum-silicon coating;

- Galvanized sheet metal;

- Aluminum-zinc coated sheet steel.

Coating quality

The last method of classification of corrugated board implies the level of quality of materials that are used in the manufacture. Today, the most common raw materials are thick galvanized steel or thin galvanized steel with polymer coating.

The polymer coating itself also has several quality levels. Suitable roof options are as follows:

- Pural. The most budgetary option with weak wear-resistant qualities;

- Polyester. A more expensive option with a more attractive appearance. However, it also has poor wear resistance. In this regard, such products quickly wear out and exfoliate;

- Polyvinyl difluorine. The most expensive option with a high level of quality and durability. Such products have excellent resistance to wear, abrasion and delamination.

It is worth noting the procedure for forming the cost of corrugated board. It depends on the following factors:

- Purpose (walls, fence, roof);

- The presence of one-sided or two-sided painting;

- Corrugation height;

- Protective layer on the surface;

- Length, width and thickness of each sheet;

- Manufacturer;

- Zinc coating.

The best decking of 2020

It's time to consider the most demanded products that enjoy a good reputation in the Russian market. All models can be divided into several basic types: load-bearing, non-structural-wall and wall. In each category, there are 1-2 good options that are worth paying attention to.

Wall models

First of all, we propose to consider products intended for finishing walls and facades of buildings. The main characteristics of such a corrugated board include a small weight and a wide range of different colors. Thus, you can choose not only a high-quality, but also an excellent option for an already finished exterior.

The thickness of such a corrugated board varies between 0.35 - 0.5 mm. This allows you to avoid increased stress on the structure. It should be noted that such products are used not only for walls, but also for fences and ceilings.

С8 Grand Line Optima Pe 0,35 mm RAL 1014

According to the overwhelming majority of users and experts, this model is the best wall sheeting in 2020. Most often, it is used for finishing the ceiling in industrial warehouses and industries. The surface has an attractive ivory color with excellent light reflectivity.

Each sheet is up to 8 meters long. Thus, it becomes possible to cover a room of impressive size without many harshness. Also, such a model is quite easy to install on a structure. This is done using conventional self-tapping screws.

Pros:

- If it is necessary to bring the edges of the sheet into a hard-to-reach place, then this can be done without additional tools. The material is quite elastic and bends by hands;

- There is a chrome layer and a primer under the polyester;

- Prevents free combustion in case of fire;

- Budget cost starting from 250 rubles per square meter;

- Attractive color that does not require additional finishing;

- The length of the sheet can be from 0.5 to 8 meters;

- Small weight, greatly facilitating the installation procedure;

- The thickness of the protective coating is 25 microns;

- Joining two sheets requires only 4 cm of sheet width. Thus, installation is economical;

- Corrosion protection. You can wipe the surface with a damp cloth and it will not deteriorate.

Minuses:

- Due to its small thickness, it is subject to mechanical stress. It is easy to dent with careless material handling.

Supporting-wall corrugated board

The next category is non-material-wall corrugated board with a thickness ranging from 0.5 to 0.8 mm. Most often, such products are used to install a fence, gates, roofing and wall decoration. This thickness allows it to withstand most loads.

C8 Grand Line Quarzit light 0.5 mm RAL 7024

This corrugated board is ideal for gates. According to many experts, this sample is the best for creating a fence, gate and wicket. The material, with a trapezoid height of 0.8 cm and a long surface of the protrusions, makes it easy to manufacture a single structure. The surface is made of polyurethane, which protects the sheets from high humidity, and also retains an attractive appearance for a long time.

Pros:

- The total width is 1200 mm. Of these, 1160 are useful. Thus, there is savings in installation;

- Excellent resistance to sunlight fading. The organic coating of the material is responsible for this;

- Good elasticity;

- Weight is 4.5 kg per square meter. This does not create unnecessary stress and gives good material stability;

- The presence of a polyurethane coating with a depth of 25 microns;

- Long service life. According to manufacturers, it reaches 30 years;

- Due to the low profile, installation is quite simple and does not require much effort;

- Impact resistance index is 18 J;

- Good resistance to moisture and salt spray;

- You can paint the surface in a different color, if the need arises;

- Technical properties are retained even at temperatures up to 120 degrees Celsius.

Minuses:

- The color is applied only to the front surface of the corrugated board. Therefore, the inner side has no decorative properties;

- High cost, starting at 620 rubles per square meter.

MP 18 1150 (1100) PE 0.5 Viking MP

First of all, we suggest considering the MP 18 1150 (1100) PE 0.5 Viking MP model in this category. Most often, this product is used to make long fences. The corrugated board in question has a layer with an impressive coating protection up to 35 microns thick. This allows the material to withstand any rainfall and exposure to sunlight at any time of the year.

One of the main advantages is the wide range of colors. Thanks to this, the model is often used for fences. The manufacturer claims a maximum service life of 25 years. However, in practice, such a fence can last even longer. The sheets themselves have a low shape with a wavelength of 18 mm. The transition lines are smooth.

Pros:

- Corrosion protection;

- Increased elasticity of the material;

- Easy to mount and dismantle due to the low profile, as well as the convenience of using additional tools;

- Matt surface "Viking", created thanks to the polymerization procedure;

- A wide range of attractive colors that do not fade over time;

- Easy to cut to size;

- Retains its technical properties even when exposed to temperatures up to 120 degrees Celsius;

- Optimal weight, which does not create additional load on the fence, but resists wind and mechanical stress well;

- Thanks to smooth waves, dust does not accumulate on the surface of the corrugated board.

Minuses:

- A small overrun of width due to increased indicators that differ from the standard;

- High cost: from 500 rubles per square meter.

Supporting products

As the name implies, such a corrugated board has excellent bearing properties. Such material can be safely used as a load-bearing structure. The thickness indicator is 1.2 mm. As a rule, such products are used for roofing hangars, powerful gates, ceilings and roofs.

C21 Grand Line Optima Pe 0,7 mm RAL 3009

Manufacturers recommend using this corrugated board for the construction of a garage or container in which things or a car will be stored. Both sides of this product have a protective layer and are also painted in a bright red color. Thus, the material does not need additional finishing. Moreover, it has all the necessary protective properties.

The wave height is 2.1 cm. This allows the product to be overlapped with different overlap levels. It depends on the prevailing installation conditions. The profile is trapezoidal and has a thickness of 0.7 mm. This allowed the manufacturer to achieve the desired stiffness indicator.

Pros:

- Attractive and bright color on both sides;

- The length of the sheets can be from 50 to 100 cm;

- The section of the wall allows the material to be used as a supporting structure;

- The presence of a primer, a chrome layer, and zinc in the composition;

- Standard weight 4.5 kg per m2;

- High level of savings during installation;

- The drawing is completely symmetrical. This allows you to make long structures without sacrificing decorativeness;

- Glossy surface, giving the material a more presentable appearance;

- Resistance to ultraviolet light, as well as a sharp drop in temperature and the appearance of moisture;

- Easy to cut with tools at hand that can be found in any garage;

- Low corrugation that can be easily screwed onto the overall structure.

Minuses:

- It is impossible to purchase sheets of increased length (more than a meter). For buildings of impressive size, you will have to install several rows;

- High cost from 600 rubles per square meter.

H75 Grand Line Optima Zn 0,8 mm

The last model of the corrugated board, which will be considered in this article, is the H75 Grand Line Optima Zn 0.8 mm. As the name implies, it is 0.8 mm thick and has a galvanized surface. If you need to make a permanent formwork, then this is an excellent option. The main feature of the material is the height of the projections, which is 7.5 cm. This ensures high-quality shape retention.

The inner surface is equipped with additional grooves that increase the strength of the frame.

Pros:

- According to the manufacturer, the service life is 50 years or more;

- Economical width;

- Can withstand high temperatures up to 140 degrees Celsius without changing technical properties;

- All components used in production are environmentally friendly;

- Does not support combustion;

- Self-stiffness and good resistance to dynamic and static mechanical stress;

- The presence of a galvanized coating;

- High strength. Even concrete can withstand.

Minuses:

- Extremely high weight 11.2 kg / m2;

- High cost from 600 rubles per m2;

- It is quite difficult to cut a sheet even with a grinder;

- Glare in the sun.