Welding inverter equipment is widely used in various areas of life: from installing a greenhouse at a summer cottage to the construction of buildings or the installation of communications. As practice shows, it is difficult to determine the line that separates household models from professional ones, therefore the choice of a good welding inverter machine for home or work can be difficult.

The TOP-10 presents the best welding inverters. The rating was developed based on customer reviews and an analysis of the best deals on the market, according to experts. The selection includes several of the most successful models of different price categories, which is a pleasure to choose from.

Content

Interskol ISA-250 / 10.6

Welding is easy with the best low-cost welding inverter at hand. The model from Interskol is an excellent device for everyone who is looking for a reliable unit up to 15,000 rubles. Beginners will appreciate the ease of use, the device does not require any skills to use, and professionals will appreciate the good power, reliability and wide range of work performed. The device is almost flawless: it copes with all tasks even at low voltage, ignites the arc on paint or rust, is equipped with anti-sticking protection, also provides an arc afterburner function and a very useful "hot start" option.

According to customer reviews, the inverter from the popular manufacturer Interskol is completely unpretentious to use, it does not heat up even with intensive use. Among other advantages, the device attracts with its compact dimensions, even taking into account the weight of 7.2 kg and its cheap cost. Judging by the technical characteristics, the inverter is intended for both domestic tasks and for professional use: the diameter of the stick electrode is from 1.6 mm to 5 mm, the welding current range (MMA) is 31 A - 225 A, the output voltage is 170 V - 242 V ...

Advantages:

- simple, convenient operation

- good power and functionality

- excellent build quality

- compact dimensions

- versatile in work

- reliability provided by high quality transistors

Disadvantages:

- length of welding cables

- electrode holder and weight from a medium quality package

Fubag IR 220

The Fubag welding machine is the same budget inverter model that perfectly “cooks with five”. Users share their impressions of the work, with an emphasis on compliance with the specified characteristics, high power and a maximum current of 220 amperes. In practice, the device is reliable, simple and convenient. The dimensions of the device are small, the weight without packaging is just over 4.5 kg. Voltage tolerance +/- 15%, the device can be used in places with insufficient voltage, for example, in the country, in the garage or in remote settlements.

The external design of the inverter confirms the impression of high-quality and modern equipment: convenient connectors for welding cables, all parts of the case are well and tightly docked, there is a strong and wide belt for carrying. The manufacturer has implemented all the necessary options: overload protection, arc afterburner, anti-sticking, “hot start”.This model is suitable for a user with any skill level, the only potential difficulty for beginners is the burning of thin metal due to the high power of the afterburner.

Advantages:

- wide range of jobs available

- the best ratio of cost and functionality

- stable and reliable performance

- high-quality equipment

Disadvantages:

- standard short wires

RESANTA SAI-190

The most popular model of a welding machine on the Russian market and in the CIS, among household-class inverters. The device has an excellent combination of price and quality. The unit is equipped with a reliable automation unit that protects the internal mechanisms from overheating, and standard options for equipment of this class: anti-sticking, "hot start". Duration of welding load 190 A - 70%, input voltage 140 V - 260 V, stick electrode diameter up to 5 mm. Decent technical characteristics and automation of work processes, together with a highly stable arc, will ensure high-quality welding of various materials, even in the hands of an inexperienced user. When choosing a good welding machine, you should pay attention to this model, an inexpensive inverter is distinguished by excellent workmanship, reliability and durability of the main technical units.

Advantages:

- good forced cooling, the device can be used even in extreme heat

- functions stably with voltage drops

- large work resource

- acceptable cost

- application of IGBT transistors

- good stability of the welding arc

- lightweight and compact

Disadvantages:

- no arc afterburner

Svarog REAL MIG 200 (N24002)

This is perhaps the best-in-class welding inverter in terms of price-performance ratio. The professional device is designed for joining elements made of ferrous metals, and perfectly cooks aluminum. The inverter is versatile and capable of welding by different methods: MIG / MAG (in shielding gas) and MMA (electrodes). Good ventilation effectively cools the internal mechanism, which allows for increased uptime. The device is easy to set up, on the control panel there are thumbs for adjusting the voltage and speed of the welding wire feed, setting the amperage. This model can be recommended for both experienced professionals and beginners: the inverter operates stably at mains voltage above 160 V, is easy to operate, and has good technical characteristics.

Advantages:

- easy polarity change

- high-quality welding with gas and without gas

- stable operation at reduced mains voltage

- built-in wire feeder

- good equipment

- increased service life

Disadvantages:

- the electrode holder is not included in the basic package

- heavy weight

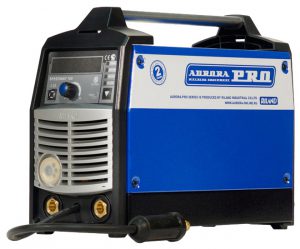

Aurora SPEEDWAY 160

One of the best welding inverter semi-automatic with three modes: manual arc MMA welding, semi-automatic MIG / MAG welding, TIG argon arc welding. Also, the unit is equipped with all the necessary functions, such as anti-sticking, arc afterburner, “hot start”. This model is a good 160 amp welding inverter designed for residential and semi-professional applications. All the information you need is shown on a small display. The welding inverter is suitable for home or summer cottages, for use in a small workshop; with a little skill, the unit will cope well even with thin metal. From user reviews, we can conclude that, despite the small indicator of the duration of use at the maximum current, the inverter surpasses many analogues in terms of reliability and endurance, and with household loads it very rarely "goes into protection".

Advantages:

- three operating modes

- good functionality

- easy to operate and reliable in operation

- precise electronic control of modes

- stability of work with voltage drops

Disadvantages:

- not intended for production loads

- high price

Fubag IRMIG 160

A good inverter from a well-known German brand is distinguished by high build quality and good performance due to automatic wire feed. The device operates in two modes: semiautomatic and electric arc welding, but due to its size and weight, it is most suitable for different types of wire. For ease of operation, the inverter is equipped with a smooth adjustment of the wire feed and current strength, depending on the material being welded, the user can easily set the desired settings. This model is perfect as the first welding equipment for a beginner, the inverter is not overloaded with unnecessary adjustments and is easy to use. The manufacturer has implemented multilevel protection of internal components against overheating, undervoltage or overvoltage, high currents. Effective forced cooling extends the continuous operation, which saves the user's working time.

Advantages:

- decent weld quality with minimal spatter

- cooks with different types of wire

- there is an electric arc welding function

- smooth adjustments, intuitive control

- good, high-quality equipment

- easy coil replacement due to convenient body design

Disadvantages:

- no function of electrode sticking

- slight deviation of mains voltage +/- 10%

Fast and Furious 200

The Forsage 200 Russian-made welding inverter is one of the best-selling models in the line. Users highly appreciated the high-quality assembly, decent "stuffing" and the increased working life of the unit. The inverter is designed to work in MMA or TIG mode, with a special torch. The device with a capacity of 200 A is suitable for any user, regardless of the experience of owning a similar technique. The control is simple and clear, all connectors are quick-detachable of the EURO type. Engineers have implemented excellent protection of internal parts and assemblies; in case of voltage surges, the device automatically turns off and requires a short pause in operation. Good assembly of the inverter is equally important, the body is durable, all parts fit snugly together, without gaps and burrs. Choosing a suitable welding machine, Fast and Furious 200 will become a serious competitor to more famous brands, thanks to a good combination of quality and reliability.

Advantages:

- perfect weld quality

- two modes: electric arc and argon arc welding

- compact dimensions at high power

- increased resource of all main technical units

- auto shutdown at voltage drops

Disadvantages:

- arc afterburner will require some skill

Cedar MIG-175GD

A professional-grade semi-automatic inverter will be the best solution when choosing a welder for construction work or a car workshop. The model is distinguished by high functionality, the inverter is designed for argon welding (TIG), for semi-automatic welding (MIG / MAG) and for manual arc welding (MMA). In the manufacture of transistors used with increased IGBT resource. The permissible deviation of the mains voltage is +/- 15%, the device operates from a 220 V network. In the MMA mode, the VRD function is provided, in addition, the device is equipped with an anti-stick and hot start option.

The power of the welding machine is 7.6 kW, the current range of MMA / MIG / MAG is within 50 A - 175 A, duty cycle is 60%. In general, the technical equipment justifies the title of "professional inverter". The model compares favorably with analogs: the device is simple and unpretentious in operation, excellent quality of the seam in any mode of operation, efficient operation at reduced mains voltage. If the task is to purchase a high-quality welding inverter with full functionality and a long service life, it is enough to limit the choice only to this model.

Advantages:

- IGBT technology application

- three operating modes

- simple polarity change

- absolute synergistic management

- excellent functionality

Disadvantages:

- not found

EWM Pico 162

Welding inverter EWM Pico 162 is designed for joining products made of low-carbon, low-alloy and high-alloy steels by MMA and TIG methods.Professional equipment is often recommended by experienced specialists in welding, the inverter flawlessly welds with any electrodes, including aluminum, even at reduced mains voltage. The control panel contains a network indicator, a thermal protection indicator and an adjustment of the MMA / TIG modes. The equipment features a high quality of work, it excellently "holds the arc" and cooks even for rust or paint. The universal model is suitable for any work and various operating conditions: for a garage, summer cottage or construction site.

Advantages:

- suitable for argon arc welding and working with electrodes

- reliable and unpretentious

- perfect quality of work on a weak network or with long extension cords

- good build

- convenient current adjustment

- German production

Disadvantages:

- supplied without complete set

ELITECH AIS 260

When you need a professional multi-purpose welding inverter, you should take a closer look at the most powerful machine in the ranking. The three-phase unit is designed for operation in industrial, agricultural and construction-repair conditions. The inverter, built on the basis of IGBT transistors, has an increased working life and guarantees a high-quality result from use. Two welding methods are available to the user: MMA and TIG. The digital display shows all the necessary information, and makes it possible to set precise settings for the amperage. Implemented protection of the mechanism against sudden voltage drops, anti-stick and hot start functions. The welding inverter has been designed for professional and responsible work: various assembly work, building erection, pipeline laying, car repair.

Advantages:

- wide range of work performed

- built on IGBT transistors

- convenient control, digital display

- high performance

- available electrode diameter up to 6 mm

Disadvantages:

- there are no objective flaws in this model

Which inverter welding machine is better to buy?

After reviewing the rating of the best welding inverters, we can conclude that a good and reliable model is not always the most expensive one. If the task is to buy a high-quality welding inverter, you need to analyze the amount of work to be done and the level of your own qualifications. Inverter-type welding equipment has firmly occupied its niche and is rightfully considered the most versatile and convenient to use; among the review of popular models, everyone will be able to choose something for themselves, be it a beginner or a professional in their field.

I prefer Foxveld welders, the most popular are the 185ka and 205ka models. Personally, I like their ease of operation, compactness, power supply from a 220V network.However, in our network it is not always 220V (sometimes less, sometimes more), so I would advise you to buy a good voltage stabilizer in the kit, and of course leggings with a canvas jacket, pants and a mask for protection.

0