Building blocks are often used during renovation and construction of new buildings. In comparison with bricks, blocks have a more attractive price, the masonry is done rather due to the large size, and the heat and sound insulation is higher. Such materials are made from various mixtures of quartz, sand, cement and fillers, using certain technologies, which distinguishes about 7 varieties of similar products. To select the best building block in 2020, this ranking was compiled.

Content

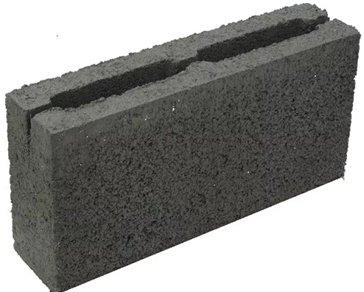

Best slag blocks

The products in question are considered to be of extremely high quality; they are produced by molding a mixture that includes slag. The filler is considered a by-product of metallurgy, so its extraction will be quite cheap. For density purposes, the poured mixture is vibrated. Often the material is used for the construction of non-residential buildings.

Sand-cement 2-hollow open bottom

It is the best cinder block for the construction of a large hangar or other enterprises due to 2 large voids in it, which helps to reduce the weight by 2 times, while maintaining the usual dimensions for such products. With a mass of 15 kg, blocks are easier to lift up for masonry purposes, and high walls are erected much faster due to the parameters of all rectangular elements.

Pros:

- an open bottom will promote deep penetration of the solution into the blocks and proper bond between the rows;

- weight 15 kg is lighter than many varieties of this group of goods;

- reliability of the structure is characterized by an indicator in M100;

- it is comfortable to hold on to the large holes with your hand while feeding materials up and during laying;

- 90 units will fit on a pallet, which will make it possible to transport large batches to large construction sites in a compact manner;

- smooth outer edges are left without further finishing, when this does not require the design of the building.

Minuses:

- high consumption of the solution due to large voids into which it will fall;

- overcharge;

- due to large cavities and thin walls, it does not withstand frost;

- when dropped from a height, there is a high risk of breaking into pieces.

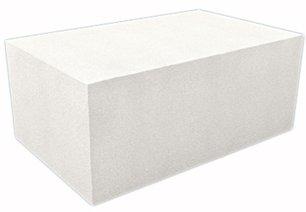

The best gas silicate blocks

Such materials will be created from cement filled with hydrogen, which will lighten the overall weight and provide increased thermal and noise insulation. This is possible thanks to the thin, smallest walls between the concrete cells, which do not allow the sound waves to be reflected and poorly transfer heat. Blocks are used to build load-bearing walls with the necessary facing, since the porosity of the material will absorb moisture and collapse.

Gas silicate partition thermocube d500

It is the best gas silicate block for the construction of a solid partition, on which it is possible to then hang furniture or household appliances. The reliability of the materials will be 500 kg per sq.cm, which withstands the loads from the dowels, in contrast to the plasterboard walls. The release of goods is carried out with dimensions of 60x25x10 cm, which will make it possible to lay large areas vertically in the shortest possible time. These blocks will not take up a large space in width (no more than 10 cm).

Pros:

- the smooth surface of the bottom and side parts will make it possible to smoothly build and further finish;

- the thermocube has a strength of 500 m, which will provide increased strength;

- large panels have an acceptable weight of 15 kg, which will allow a person to carry and put them without an assistant;

- 80 pieces are placed on a pallet, which will be beneficial during the delivery of large quantities by a machine to a construction site;

- 1 truck will fit 1280 units;

- economical solution consumption due to the absence of voids.

Minuses:

- overcharge;

- a width of 10 cm is more difficult to grasp with a master with short fingers.

D600 B3.5 1 Grade Gas silicate block Poritep

They are the best gas silicate building blocks suitable for the construction of load-bearing walls of residential multi-storey buildings due to their increased density with M600 indicators, which can withstand significant loads. The construction element has a snow-white shade with optimally even outlines, which is comfortable during dry laying for storage purposes and when forcing walls. There are no voids in the structure, which helps to moderately consume the mortar and create masonry of high heights.

Pros:

- an extremely smooth surface makes it possible to finish the blocks with the smallest thickness of plaster or putty from the inside;

- large dimensions 62.5 cm long and 25 cm high will make it possible to erect walls in the shortest possible time;

- it is possible to choose the width from the assortment in the range of 50-500 mm, which will facilitate laying in 1 row and provide a thick wall size;

- increased material density;

- low heat conductivity of 0.13 will help keep it indoors;

- vapor permeability no more than 0.16 prevents mold and mildew from forming in the corners of the structure;

- shrinkage at the end of drying of the masonry does not exceed 0.28 mm per m;

- frost resistance will be 100f;

- the material is fully non-flammable.

Minuses:

- it is extremely uncomfortable to lift large blocks up and put them in 1 row (large dimensions);

- overcharge;

- it will take the actions of 2 people to put large elements on the wall with high quality.

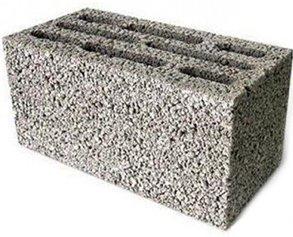

The best expanded clay concrete blocks

This material is made from expanded clay with further pressing, which increases its reliability and bearing capacity. A building product of this quality does not require facing, as it does not absorb moisture enough. However, the unsightly appearance makes it possible to use it for utility and industrial buildings.

Expanded clay concrete partition hollow

It is the best solution to build a partition in the back room due to the price of a large block. One product unit covers 39 x 19 cm of vertical space. The thickness of 18.8 cm will provide adequate dimensions for 1-row masonry. Sound permeability has a delay rate of 41 dB, which helps to reduce the propagation of sound waves while working inside.

Pros:

- reliable installation in a row due to the presence of 3 longitudinal voids, which take part of the solution for the base;

- it is comfortable to grip large grooves with 1 hand;

- small grain size of the composition will provide a smooth surface, which can be left without finishing work for rooms;

- walls made of this material retain heat due to heat conductivity indicators not more than 0.43;

- adequate cost;

- voidness is not more than 20%;

- comfortable weight of 6 kg, from which the hand does not get tired;

- more than 200 pieces will fit on the pallet;

- compression reliability 35 MPa;

- a car with a lifting capacity of 20 tons can deliver 3360 units of products at a time.

Minuses:

- the material is suitable for indoor work due to frost resistance f25.

Expanded clay concrete 8 hollow m75

It is the best lightweight aggregate concrete block for the construction of large enterprises, as it is characterized by parameters 39x19x18.8 cm, which will provide quick laying and proper wall thickness in 2 rows.

From the inside, there are 8 voids: 4 long and 4 short, which helps to lighten the weight and increase the strength of the structure of the partitions, which do not have a solid line (this increases the reliability of the frame of the building element).

Pros:

- the solution will fall into the void and help to tie the rows tightly;

- increased productivity due to large dimensions;

- the internal cavities are narrowed, therefore the solution is not too consumed due to the failure;

- despite the large size, the weight of the product will be 15 kg;

- material density 1.2 t per cubic meter m will withstand significant static load;

- will meet the standards;

- such material effectively isolates the industrial noise inside due to the indicators of 45 dB;

- the release of heat is protected, which is not observed in all brickwork;

- there are 120 pcs in the pallet;

- more than 1600 units fit in a 20 t car.

Minuses:

- overcharge;

- dim view of the side part (looks bad without further finishing work);

- reliability is not very high, therefore, during operation, you need to be careful, since the block will crack from falling;

- not too high frost resistance.

The best foam blocks

Similar materials are used in the construction of load-bearing walls due to their increased strength and low vapor permeability. The block has pronounced contours and a finely porous structure due to the presence of solid foam in the composition, which provides a small mass and thermal insulation. Drilling the walls is permissible without special nozzles, which will facilitate the further installation.

AeroStone D500

It is the best foam block for construction at a high pace due to its length of 62.5 cm. The user has the option of choosing the height of the element in the range of 20-25 cm, taking into account the required dimensions of the structure. The blocks are produced in width in the range of 100-400 mm, which makes it possible to create thin structures from the outside or load-bearing supports. The reliability of the material will withstand increased loads.

Pros:

- a sufficiently smooth surface will provide the least curvature during distribution of the solution;

- heat conductivity is rather low;

- adequate resistance to frost;

- insufficient steam conductivity;

- there are no voids that absorb the solution;

- there is no significant shrinkage at the end of drying;

- the material does not fully burn and provides adequate protection;

- during compression strength - 2.5 MPa;

- inside the dwelling, finishing work will be needed in a small layer due to the fine-grained block wall.

Minuses:

- overcharge;

- the foam block absorbs water from rains, therefore you will need to carry out a thick finish outside;

- large foam blocks are uncomfortable to take.

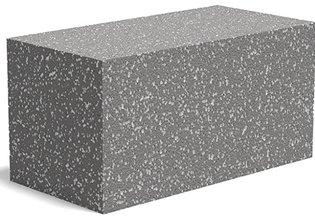

The best polystyrene concrete blocks

This type of building blocks has cement as a binding element and large crushed stone with sand in order to fill and secure the structure. Polymer fillers will provide low heat conductivity and increased noise insulation, therefore the material is often used to insulate buildings.

Polystyrene concrete d250

They are the best polystyrene concrete blocks for arranging load-bearing walls, as they make it possible to increase the thickness by 12-24, taking into account the selected option. In length, the panels are presented in 2 types of 59.5 and 37.5 cm, which is comfortable during the construction of corners and during the lining of openings for windows. Delivers material on pallets, coarse structure with polymers for proper insulation.

Pros:

- the reliability of the composition will effectively withstand the static load;

- low density in the range of 150-600 kg per cubic meter m will provide low weight and comfort while working with blocks;

- has one of the lowest heat conductivity coefficients;

- the asexual structure absorbs the solution to a lesser extent;

- increased performance for noise insulation;

- allowed to use in 3-storey buildings;

- it is possible to put on a solution and on special glue.

Minuses:

- low strength needs extremely careful handling during work;

- overcharge.

The best foundation blocks

This type of building material is used to create a support for buildings with different numbers of floors. Unlike tape bases, they do not need formwork and long solidification. Install blocks on the solution in increments.

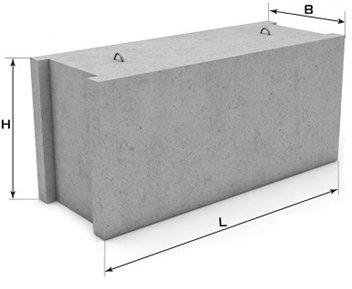

FBS 9-4-4

It is the most effective foundation block when creating an extremely strong foundation. This is due to the presence of reinforcement, which increases the resistance to all kinds of loads. The dimensions make it possible to carry out work in the shortest possible time, covering large areas with 1 large block. The side pieces will ensure the integrity of the unit during installation.

Pros:

- for hanging on crane hooks, 2 metal loops are provided;

- reliable reinforced concrete structure;

- will withstand a significant load;

- there are no cavities;

- width 38 cm assumes installation in 1 row;

- silicate additives increase thermal insulation;

- has good water resistance.

Minuses:

- overcharge;

- significant weight requires the use of a crane;

- difficult transportation.

The best ceramic blocks

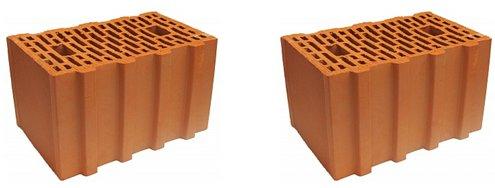

The material under consideration is made of molded clay with further annealing with increased temperature parameters, which gives reliability. They are used during the laying of walls and fences. This form of products makes it possible to erect a structure in the shortest possible time, and have a look that is similar to brickwork, but with greater productivity.

Braer 38

It is considered the best block in the segment under consideration for fast methods of building construction due to its dimensions 38x25x21.9 cm, a multi-floor structure that contributes to a low weight and increased strength of material installation in a row. The alternation of the parameters of the cells will provide a chaotic position of the partitions inside and evenly distribute the load. The outer walls are provided with ribs that provide high adhesion to other finishing materials.

Pros:

- large blocks are comfortable to lift due to the presence of multiple protrusions;

- m100 makes it possible to use them for the construction of a multi-storey building;

- low heat conductivity makes it possible to save energy resources;

- comfortable weight during construction;

- there are 60 pcs on the pallet;

- small holes will prevent the solution from getting deep into the voids;

- in a car with a carrying capacity of 20 tons, it is possible to transport up to 1100 units;

- voidness will be 60%, which does not create a load on the base with thick walls;

- the material does not pull water inside due to insignificant water absorption of 11%;

- there is no chamfer, which will make it possible to control the uniformity of the seams.

Minuses:

- overcharge;

- further finishing will be required due to effective frost resistance.

Criteria for the selection of building blocks

The question often arises as to which building blocks are best for construction. Blocks are intended for structural, structural and thermal insulation, thermal insulation purposes. In this regard, it is required to familiarize yourself with the following recommendations:

- The strength of the material. The ability to withstand some physical activity. To find the right blocks, you need to familiarize yourself with the brand. For example, brand M - 50-150. This indicates that the material will be able to withstand loads in the range of 50-150 kg per square cm. For example, a foam block is marked with characteristics 0.25-12.5, and therefore, building a load-bearing wall from it will be a mistake. In the network, it is possible to find summary tables of the strengths of building blocks and carry out the calculations required for a specific need.

- Relation to various temperature indicators. Emphasis should be placed on the frost resistance of materials: any building block withstands a certain number of complete freezing and thawing cycles, then it collapses. Even in high latitudes, the walls will not fully freeze through, therefore the indicators will be conditional.The degree of frost resistance 35 (the number of complete freezes) is considered sufficient, most of the lightweight concrete blocks have it. For ceramic products, the characteristics will be 50.

- The ability to absorb moisture. Concrete will give way to bricks, because walls from any type of block require exterior finishing works of facades. Therefore, the finishing procedure should not be delayed.

Based on these recommendations, it is possible to choose the best building blocks for your home.

The question often arises as to what are the best building blocks to buy. To purchase a quality product, this list was compiled. The list includes the best blocks. They are characterized by reliability and quality.