The use of technology is always closely related to its maintenance and repair, and chainsaws are no exception. One of the most common tasks is to replace the sprocket on a chainsaw - an element of one of the key components. The wear can be natural, caused by a wrong tire or poor quality part.

It is useful for each owner of such a tool to know how to remove the sprocket from the chainsaw correctly and replace it. DIY repair saves both time and money. And also quickly bring the tool into working order, because for this you do not need to wait for an appointment at the service, it is enough to purchase the necessary parts.

Content

How to remove an asterisk from a chainsaw - detailed description

How the clutch system works

In most cases, a centrifugal clutch installation is used on Shtil, Partner, Husqvarna and other brands of chainsaws. When the engine picks up a certain number of revolutions, it turns on automatically, transmitting rotational movements to the sprocket.

The clutch is a disc located in a drum. The entire unit is attached to the chainsaw engine shaft. In the normal state, the clutch springs press the friction linings, preventing the transmission of motion to the drum, respectively, and to the sprocket. When the revolutions reach a predetermined value, a centrifugal force is generated, under the influence of which the elements with friction lining are displaced, putting pressure on the inner walls of the drum. Thus, the sprocket is driven by rotating the saw chain.

Why is it necessary to replace the drive sprocket

Chainsaws have some parts that are subject to natural wear and tear, such as the chain, bar and drive sprocket. This is not considered a tool breakage because wear is the result of use. Also, an unsuitable chain or mechanical shock can become a causal development. For example, after meeting the chain with a metal object, it is recommended to inspect the sprocket.

If the part is not replaced in a timely manner, the stability of the tool is impaired. A worn part provokes unnecessary vibrations, which in turn have a negative effect on the crankshaft bearings.

Wear of teeth up to 0.5 mm is considered normal. However, users often bring the part to a deeper development of the order of 1 mm, unaware that operation damages other parts of the chainsaw. Naturally, subsequently there is a breakdown of the bearings, which must be replaced.

Step-by-step instructions for replacing the sprocket on a chainsaw

You can replace the asterisk on the chainsaw not only in the service, but also with your own hands. The whole process is relatively simple, for repairs you will need:

- candle key;

- a wrench for removing the clutch (an ordinary Bulgarian nut wrench is also suitable, but it is desirable that it be thicker);

- piston stopper (special tool, but it can be replaced with a tight cord);

- adjustable / wrench (may not be useful).

Step 1... Replacing the drive sprocket and chain begins with fixing the piston in the cylinder of the chainsaw.To do this, remove the upper housing cover, air filter, and unscrew the spark plug. A special piston stopper is installed in this hole, but it is not in great demand among craftsmen: a metal one can scratch the piston, and a plastic one can break and get inside. Most often, instead of it, they take an ordinary dense cord or wire about 10-15 cm long. It is important that debris does not fall from it, metal wires do not stick out - all this can get into the cylinder.

Install the stopper or cord into the hole. The piston may get in the way; to lower it, you will need to turn the sprocket slightly, moving the chain or itself clockwise.

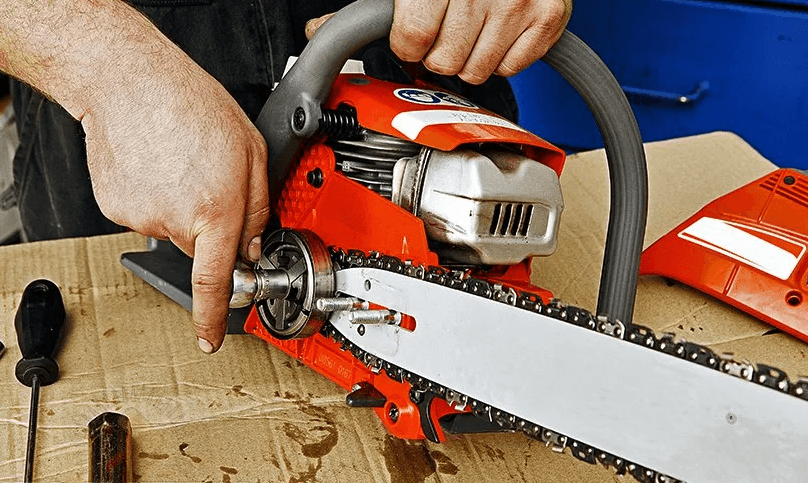

Step 2... Remove the cover from the side of the chainsaw where the bar is attached. It is usually held in place by two bolts and secured with two nuts. They can be unscrewed manually or with a wrench or allen key. The tension on the chain is released so that the chain and bar can be removed immediately. At the same stage, external cleaning of accumulated dust and sawdust should be carried out.

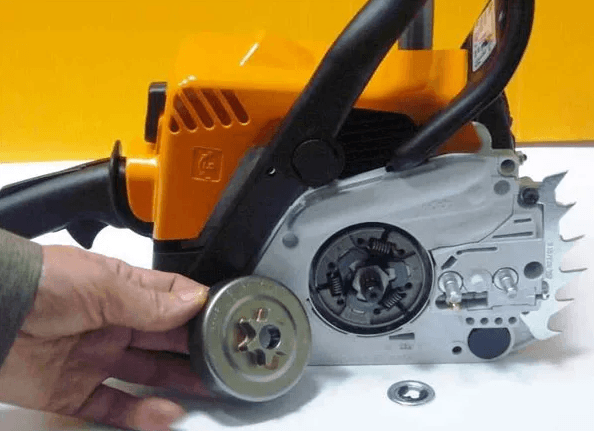

Step 3... Depending on the design of the chainsaw, the sprocket can be located under the clutch drum (separately or be part of it) or on top. In the second case, everything is easier - remove the part and replace it with a new one.

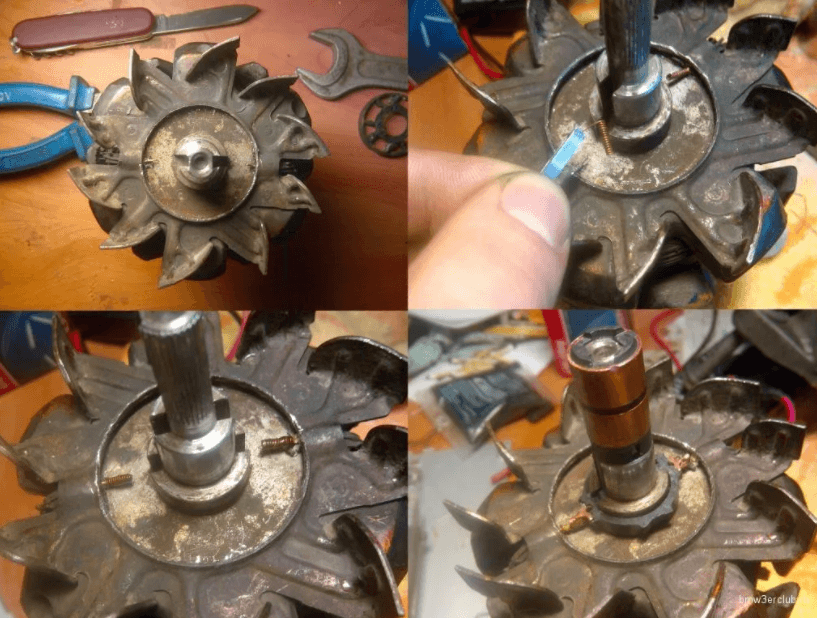

Under other circumstances, the assembly must be disassembled. The coupling is with a left-hand thread, so it is unscrewed clockwise with a special or Bulgarian wrench, the drum is removed, then the sprocket can be removed. If the chainsaw has been used for a long time, parts can become very sticky. In such a situation, physical force will be required, however, it is forbidden to use a hammer or chisel - this will render the entire part unusable.

Step 4... Extract all details:

- clutch

- washer

- drum

- asterisk

Perform an initial inspection of all elements for wear and deformation. Then you can start repairing and take on the replacement of the sprocket on the chainsaw. If it is part of the clutch drum, the entire part must be replaced. An important point will be the selection of a new part - it should be similar to the standard one.

Instrument assembly order

The chainsaw is assembled in the reverse order. First, the sprocket is installed on the needle bearing, then the clutch drum, washer and the clutch itself. Twist it counterclockwise, but lightly. The piston will also need to be fixed, but with left rotation a few millimeters before the maximum upper point.

Note that sometimes the oil actuator is equipped with a spring that transfers motion from the sprocket to the pump. If the spring must not fall into place, the oil will not be supplied to the chain. Usually, the correct position is marked with color, risks, in the absence of those, you need to slowly rotate the part until a characteristic click.

Next, you need to install a saw bar on the chainsaw. To put the chain, you need to release the handbrake by pulling the lever towards you (towards the handle). It is important here that the chain teeth fit into the sprocket grooves. Inadvertently, this moment can be missed, which will lead to a quick damage to the chain. Its correct direction is indicated on the body with characteristic pictograms. After installation, it must be pulled to a working condition.

At the end, you need to remove the piston stopper, install the spark plug, air filter in place. Secure the top housing cover.

If you need to remove the sprocket from the chainsaw in order to replace it with a new one, the spare part must be purchased in advance. Otherwise, you can take a worn out part and contact a specialized store with it, where the seller will help you choose an analogue.

Watch the video how to remove an asterisk from a chainsaw

Useful Tips

In order for the chainsaw mechanism to last longer, you need to adhere to certain rules. Experienced craftsmen recommend:

- Always lubricate the needle bearing after replacing the sprocket.

- Select the correct saw chain and bar. The sprocket and chain pitch must match (eg 3/8 or 0.325).If unsuitable consumables are used, the sprocket flares up, wears out quickly and unevenly.

- Many people try to replace the drive sprocket and chain at the same time. The fact is that as you use the chainsaw, the chain inevitably stretches, and accordingly, the length of its step also changes. And this already negatively affects the sprocket itself, in particular, a wide step will wear it out faster, breaking the grooves at the edges.

- Be sure to clean your chainsaw regularly. From time to time it is necessary to remove the side cover and remove the accumulated sawdust, which inevitably gets through the hole near the chain and mixes with the lubricant.

- Observe the "behavior" of the chain during operation. If it starts to wedge, this is a reason to make an initial inspection of the drive sprocket.

Outcome

The algorithm of actions when carrying out repair work on a chainsaw is quite simple and is based on the experience and knowledge of qualified craftsmen. Therefore, it is not recommended to neglect these or those nuances. The instruction presented by us will help you remove the sprocket from the saw with your own hands, without resorting to the help of specialists, on most types of chainsaws. In private, any deviations, non-standard designs are not excluded. Sometimes it is very useful to read the user manual for the tool, it may contain the necessary information about the design features, details of spare parts with a description.