Many types of construction work involve the manufacture of various mixtures and mortars. Previously, a person did it by hand, mixing cement, sand, water and other necessary ingredients on his own. However, with the development of technology, special devices began to appear to automate this process. We are talking about a concrete mixer, in which it is enough to put the raw materials and start. In recent years, not a single construction site is complete without such equipment. However, not everyone knows how to choose a concrete mixer for the home, despite the fact that this is a rather important process on which the efficiency of work depends. in which the concrete mixer will be used. In this regard, it is worth knowing which model is better to choose and what characteristics are worth paying attention to.

Content

General operating principles of modern concrete mixers

To figure out which concrete mixer is better to choose, first it is worth considering the general principles of operation of such devices. First of all, let's consider the design itself, which includes various modules. Each of them is responsible for their own processes during the operation of the entire mechanism:

- Drum. The main workspace of any concrete mixer. The raw material is placed here, which is then processed by the machine. It should be noted that, depending on the model, the drum can have a different shape. It can be a cylinder, barrel, cone, cylinder, or pear.

- Frame. This module is only necessary for the stability of the structure. A barrel and other technical elements are attached to the frame. Some frames are equipped with casters for increased mobility.

- Control block. It can be made in any form, depending on the manufacturer or the model itself. However, the main principle is the communication between the user and the system. Here you can turn the mechanism on or off, as well as adjust the speed or other parameters.

- Electrical engine. Everything here is as simple as possible. It is necessary in order to set the drum in motion, thereby stirring its insides. And also the motor makes the blades rotate.

- The last element of modern concrete mixers is the paddles. They are necessary for thorough mixing of the raw materials placed in the drum. Prevent any portions of the mixture from sticking to the drum walls. Made of metal.

Now let's look at the principle by which modern concrete mixers work. There are two basic principles that depend on the type of concrete mixer itself. It can be gravitational or forced.

In the first case, the blades are in a fixed position and only the drum is spinning. Thus, the mixture in the drum rises and falls cyclically under the force of gravity, passing through the blades. After that, the user changes the angle of inclination of the drum, which allows unloading the finished batch from the container.

As for the forced form of the mechanism, here everything is the opposite. The drum does not move, and the blades work continuously inside, stirring the solution. In this case, there is no need to change the drum angle. It is enough to open a special compartment in the bottom and unload the contents.

The main types of concrete mixers

Now let's look at the main types of modern concrete mixers. Aggregates of forced and gravitational action were identified earlier. However, there are still girth and gear models. It is worth considering each species in more detail.

Gravity Concrete Mixers

The principle of operation of such models was discussed in the previous section. Here we will consider their advantages and disadvantages.

Pros:

- Reasonable cost relative to other analogues;

- Easy operation;

- They do not require special care;

- Simple and reliable design;

- Suitable for most mortars, not just concrete.

Minuses::

- Quite a lengthy procedure for thorough mixing. Not suitable for operational work.

Crown concrete mixers

This type of concrete mixer is often used by small private construction companies. However, some people buy such a unit for personal use. On the edge of the drum, there is a special ring gear with an impressive internal diameter, which is used to stir the solution.

The main disadvantage of such concrete mixers is that the crown in question is prone to contamination and can quickly fail. The second depends on what material this crown was made of. Today, cast iron, polyamide or steel are used in production. Cast iron is most often found, since it is easiest to make it for a concrete mixer. However, it is highly susceptible to mechanical damage and can fail if the user makes an operating error. At the same time, the part cannot be repaired and you will have to buy a new one.

Polyamide is much better in this regard. It is less susceptible to stress and environmental influences. In this case, even if a breakdown occurs, the device must be restored. As a rule, a polyamide crown has 4 interconnected modules. This makes repairs much easier as there is no need to replace the entire part. It is enough to replace only the damaged one.

And finally, the crowns of the most expensive concrete mixers of this class are made of steel. The cost is due to the fact that the production of gear steel is quite labor intensive and costly. Therefore, it is the least popular type of ring concrete mixers.

Pros:

- Suitable for processing mixtures containing large elements;

- Attractive cost (not counting steel crowns);

- Low energy consumption;

- Easy to unload the ready mix from the drum without effort;

- It does not require special care.

Minuses:

- It is not recommended to use it to form a viscous mixture, since efficiency decreases;

- Small volumes of containers.

Compulsory concrete mixers

Compulsory concrete mixers were discussed in the previous section. Such devices have their own specifics and it is recommended to use them for certain types of mixtures for the following materials:

- Hard or slow-moving concrete;

- Curbstone;

- Dense or porous filler;

- Brick;

- Paving slabs;

- Concrete blocks.

Pros:

- Such devices have a long service life;

- High mixing efficiency;

- Prompt formation of the desired consistency of the mixture;

- It can work with both liquid and stationary solutions.

Minuses:

- The density of different elements of the feedstock should not differ much from each other, except for ordinary water;

- Excessive energy consumption.

Gearbox concrete mixers

Gearbox models are considered the most versatile, since they can work with almost all types of mixtures of various consistencies and fractionation.All large construction companies use these concrete mixers. However, sometimes they can be found in private production.

Pros:

- Virtually no noise during operation;

- Favorable position of the gearbox, which does not allow it to get dirty during work.

Minuses:

- The gearbox is susceptible to mechanical damage. If it fails, then the repair will cost a round sum;

- Requires special care and accuracy of use.

Most popular brands of concrete mixers

Before considering the most important technical characteristics of concrete mixers, which you should pay attention to when choosing, we suggest that you familiarize yourself with the list of the most popular manufacturers of modern devices today. If you do not have the time or desire to understand all the intricacies of the work of the products in question, then you can simply purchase a high-quality model from a trusted brand that has earned the trust and reputation among users.

Today, the following brands are considered the best manufacturers of concrete mixers around the world:

- Inforse;

- Profmash;

- Lebedyan;

- Denzel;

- ZITREK.

By purchasing a concrete mixer from one of the above manufacturers, you are guaranteed to receive a high-quality and reliable mechanism that will not let you down over time. If you want to delve deeper into the issue, it is recommended that you familiarize yourself with the parameters for choosing a concrete mixer.

Choosing a concrete mixer for a summer residence: selection parameters

Electric motor power

The power of the engine determines not only the number of revolutions of the drum or blade per second, but also its ability to process a certain amount of raw materials, as well as the maximum size of its fractions. For private use in the country or in small construction, power up to 1000 watts will be enough. Moreover, the higher the production volumes, the higher this indicator. Thus, for large objects, it is recommended to buy a model with a motor power of more than 1000 W.

Drum capacity

It is also quite an important indicator, which should directly depend on the volumes with which you plan to work. Today you can find models with a drum from 50 to 300 liters. It all depends on the purpose of use or individual preferences of the user.

Rotational speed

This indicator should not be too high or too low. The most optimal level is considered to be from 23 to 30 rpm. It is important to know that the more revolutions per minute the drum makes, the faster the finished solution will set.

Final mix volume

It is worth considering the indicator of the final volume of the solution. The fact is that during the operation of the concrete mixer, the volume of the mixture decreases. The most optimal indicator is 60% of the original volume. It should be borne in mind that it is not recommended to fill the entire volume of the drum, since this can overload the engine or reduce the efficiency of the shift formation.

Crown material

If you decide to purchase a crown mixer, it is extremely important to pay attention to the material from which the crown itself is made. It is not recommended to buy models made of cast iron or steel. The former cannot be repaired and often break down, while the latter are too expensive and not worth it. Thus, polyamide crowns will be the best option.

Voltage level

The voltage indicator allows you to determine for which types of work the manufacturer made this model. If the indicator is 220 Volts, then this is a device for private use at small construction sites. If the voltage is 380 V, then this is a unit for massive construction sites, where it is possible to connect to a three-phase power grid.

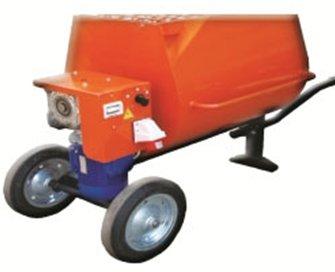

Swing mechanism and wheels

A concrete mixer becomes much more mobile and convenient if it has wheels for movement, as well as a swivel mechanism. For turning, not only wheels can be used, but also a special lever. It all depends on the specific model.

Popular models

Consider a few of the most popular models of concrete mixers that are in good demand and have attractive reviews today.

Denzel B 200

Many consider this model to be the best of its kind. This is a gravity concrete mixer with a power of about 1000 watts. Moreover, the capacity of its tank is 200 liters. The main feature of the model in question is that its manufacturer has provided for a copper winding. Thus, even if the mains voltage drops, the mechanism will continue to work for some time. The control unit allows you to adjust the position of the drum and fix it in the desired one.

The model must be connected to a network with a voltage of 220 V. It is worth noting the presence of technological protection against overloads, due to which the risk of breakage, looping, overheating or other unpleasant phenomena is reduced to a minimum.

Pros:

- Impressive power of 1000 watts;

- Acceptable cost up to 15 thousand rubles;

- Copper motor winding;

- High-quality assembly from reliable materials;

- High drum volume.

Minuses:

- The crown is made of cast iron;

- Unbreakable bowl.

Caiman MIX60PLUS

Consider a concrete mixer that works on the principle of forced action. We are talking about the Caiman MIX60PLUS model, which allows you to form a small amount of the desired mixture as quickly and easily as possible. The drum volume is only 56 liters (47 liters of ready-mix). However, this can be called an advantage of this model, since it copes with such an amount of solution as quickly as possible. It also makes it much easier to transport the device.

Pros:

- Reliable manufacturer from France;

- Long warranty period;

- Low weight, good transport properties;

- Reliable and high-quality assembly made in Italy;

- Considering the size of the structure, a good power is 550 watts.

Minuses:

- Extremely high cost relative to other models.

MISOM SO 351-300

The next step is another compact forced-action concrete mixer, the drum of which holds significantly more mortar than the drum of the previous model. The volume here is 250 liters. Moreover, the mechanism is equipped with everything necessary for efficient operation. The production of the model has been established in Belarus.

Pros:

- Power is more than 2000 watts;

- Great for both private and large-scale use;

- Low noise level during operation;

- Drum volume 250 liters;

- Compact dimensions when comparing the model with gravitational counterparts.

Minuses:

- Impressive value.

Caliber TSE 65/220

The last concrete mixer that will be discussed in this article is called the Caliber TSB and is based on the gravity principle. As the name implies, it is intended for private use, since it is connected to a network with a voltage of no more than 220 V. This is a fairly budget model that is perfect for giving. The volume of finished products after one cycle is almost 50 liters.

Pros:

- Budget cost;

- Easy operation;

- Compact dimensions;

- Easy transportation.

Minuses:

- Unreliable crown;

- Too short network cable, you will have to use an extension cable;

- There is no minimum engine cooling system, which makes it problematic to use the model continuously for several hours.