Since ancient times, craftsmen have used such a tool as a plane for wood processing. True, in Europe it became more common in the 15-16th century. This is a kind of wooden block, inside which there is a metal blade reinforced with a wedge. Subsequently, the design underwent some changes, and therefore a metal frame replaced the deck.

As electricity spread, electric planes were also built. In the industry today, more and more often use planing and thicknessing machines. But for household and construction needs, mobile electric planers are used, which are distinguished by high power indicators and the depth of wood processing.

Realizing that the correct selection of a tool can be compared with a whole block of science, we decided to raise the issue in an article on how to choose an electric plane for the home.

Content

- 1 List of leading manufacturers: which company to give preference to when buying a planer

- 2 The advantages of electric planers

- 3 The main disadvantages of electric planers

- 4 Basic principles of operation

- 5 Features of work

- 6 Technical characteristics: choosing the right tool

- 7 Price question: how much does a good electric plane cost

- 8 Additional structural elements

List of leading manufacturers: which company to give preference to when buying a planer

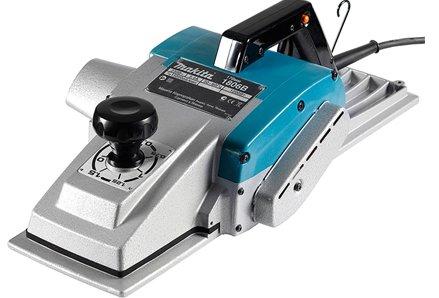

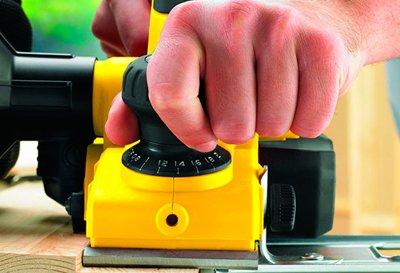

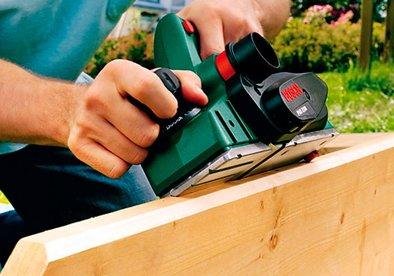

Choosing which construction tool to choose, in this case it is worth pointing out that the leaders in the market were and remain companies from Germany or Japan. By delving into the features of electric planers, you will understand that you need to study a number of parameters in order to make the right choice. If you do not have such a desire, you can pay attention to the tools of these brands: DeWalt; Makita; Bosch; Skil; Hitachi.

But keep in mind that each of the companies presented represents a wide variety of models, and therefore it is likely that the help of a sales assistant will be required.

Planer design features

An electric plane for summer cottages will be the best assistant if you need to level a flat wooden surface or eliminate irregularities and roughness. The result can be achieved with planing, i.e. removing thin chips from the outside. In this case, the surface will acquire smooth features, i.e. all knots and hindrances will be excluded.

A board that is planed correctly will have a glossy base and a polished look. Natural wood grain will be visible on the surface. Unlike sanding wood, when only the top layer of up to 1 mm needs to be processed. In the case of planing, a layer of 4 mm or more will be removed. The most accurate processing will be called scraping, if we refer to the terms of specialists.

If it is an electric tool, then, unlike a hand planer, several basic options will be connected in it. This can be chamfering, cutting a quarter, grooving. In addition, the tool is used as a jointer, which is a stationary planer fixed on the worktable. The ruler of the additional level, like the square, makes it possible to align the workpiece and give it a rectangular shape.

The advantages of electric planers

The main positive qualities of the tool are that the performance indicators are really high, the application of physical effort is excluded. You can also use the device in the form of a thicknessing equipment or a planer.

The sampling of a quarter is of the highest quality, and even when working with the tool, the owner will save finances. Planed lumber is 1 times higher than rough in terms of price.

The main disadvantages of electric planers

But even the best tool can have disadvantages for its owner. This time they boil down to the fact that these types of planers are not used to level the floors, i.e. scraping. Serious injury could result if you are not careful while working. The drum with knives will rotate at a really high speed.

The device is not capable of replacing hand tools, which are designed for the purpose of machining end faces and corner surfaces. They will need to be finalized with a complementary planer or a falzgebel.

Basic principles of operation

An electric planer should be understood as an analogue of a standard tool, which still adheres to the goals - to remove the top layer of wood in order to create an exceptionally flat surface.

Unlike the mechanical type of the device, where everything will depend on the magnitude of the vertical pressure on the part of the specialist and the applied force of the longitudinal guidance, the plane itself "bites" into the wood mass and chooses a certain layer due to the high-powered motor and knives that will rotate.

Due to this tool, it will be possible to carry out the work of planing, sampling a quarter, beveling the edge and fitting wood elements that are adjacent to each other.

This tool is reflected in the production of furniture, window sills, benches, frames, arbors. It is used after the wood has passed the rough processing stage. As a rule, trunks tend to bloom on a sawmill, which are supplied in the form of rough planks and squared beams.

Due to the drying process, it is possible to remove excess moisture accumulation, but note that the plane will be pretty deformed. The coarse fiber structure, as well as the unevenness of the wood, will need to be reworked later. For these purposes, a tool is used that will help create a surface with a smooth base.

At the last stage, the product can be sanded using a machine equipped with flap wheels. It will be ready for painting and varnishing.

To ensure the process at a high level, manufacturers have made a lot of effort and were ideally able to think over the design features of the device.

The device includes: a drum with knives; electric motor; main handle with start button; Belting; depth regulator; auxiliary handle for holding, even pressure; sole; linear and limiting devices of an additional plan, as well as a channel for removing chips.

Features of work

The tool works on the principle of rotation of an electric motor, which is powered from the mains. The toothed belt drive is protected by a casing. It connects the engine and drum to each other. The latter device has blades as well as a matched angle. It cuts into the plane of the surface, while moving in parallel.

In order for the depth of penetration into the material to be adjusted, there is a base, which specially has a system of 2 parts. These are back and front designs. One of them is able to move up and down, and the second remains at the same level, being equipped with a cutting type of drum.

Due to the difference that occurs with the height of the parts of the ski, it is possible to create a special drop where the blade cuts. It determines the depth to which the material will be cut.

During the production process, the removed layer of wood in the form of dust and small shavings will be discharged through the channel to the side.Some models have a bag attachment that can reduce the amount of sawdust in the air. In each case, to use the plane, you should wear safety glasses.

Types of electric planers

Professional purpose

Power indicators from 1 - 2.2 kW. These values are sufficient to cope with a number of tasks, even in a woodworking factory or a private workshop.

This type is practical when it is necessary to manufacture furniture, frames, doors and other structures. It is convenient to work with it, even if it is a solid wood of the massif, for example, ash or oak.

The tool works for a long time, even if you use it every day.

Main advantages

- high power indicators;

- application all day;

- availability of additional devices;

- works at high speeds;

- the depth can be adjusted up to 18 meters;

- large area capture;

- the surface is very smooth after processing.

Main disadvantages

- expensive model;

- heavy by weight.

For home and garden

The main parameter of electric planers for home and summer cottages is a power indicator of 0.5-1 kW. The potential is quite enough to perform one-time and small tasks that often arise in everyday life.

When used every day, and even in non-stop mode, they will not be effective. The performance of the device is low, and therefore it will quickly fail.

Main advantages

- acceptable price;

- precise depth settings;

- the weight is not large;

- power indicators do not exceed a parameter of 1 kW;

- handles in work are as comfortable as possible.

Main disadvantages

- all the necessary accessories for this type are not on sale;

- difficulty when working with hard wood.

Technical characteristics: choosing the right tool

In fact, it is worth choosing an electric planer, relying on the conditions in which you intend to use it in the future. If this is homework, then you should not pay attention to the professional appearance of the device, which is distinguished by its high cost and power indicators. The technique, as it became clear from the above information, can work every day, at maximum load. At home, such parameters are simply useless.

You may need an electric plane to cut the surface of a board that is 3 cm thick. there is no point in overpaying. Evaluate rationally the scale of work that will need to be done by the tool, and only then make a decision to buy it.

Take into account the technical parameters that are indicated in the passport of the device. It should be included with the tool. It is better if the documentation is in your own language so that there is no misunderstanding. This is another fact that the supplier is not a one-day company and has been operating in the domestic market for a long time, with prospects for the future.

Appearance

This parameter for the tool is not the main one when it is selected. But relying on it, you can understand the degree of professionalism of the device. Many organizations paint the surface of the plastic case in the desired color, thereby highlighting its belonging to the species. For example, all Bosch instruments from Germany are presented in blue and green. The latter option indicates home use.

There are also those manufacturers from Asia who, as a rule, are not conscientious. They use this gradation and paint the devices blue, thereby designating them as quality devices.

Makita's company paints the planes blue, and Hilty's red. Devalt devices are sold in yellow tones. Those. paying attention to the colors, you can distinguish a low-quality fake from the original products of brands with an excellent reputation.

Another feature is that the design is ergonomic. Here it is worth noting just an elegant design, but also ease of use, compact properties, and the absence of sharp corners in the device.Leading brands from all over the world take this parameter with great importance. You cannot say this about small organizations that produce goods, which are not distinguished by the ease of use, in fact, as well as by the quality.

But keep in mind that the entire load is assigned to the body during operation. The logical consequence of this is the use of quality plastic for the application. During construction work, sometimes the tool can fall on the concrete floor, and its use is associated with a large level of dust. The visual hallmark of a good quality plastic case is its gloss and the absence of parts that are fragile or thin. If the tool is sold in a case from the manufacturer, then this is a sure sign that you have quality products. Moreover, the kit may also contain spare parts in the form of drills, replacement knives and graphite brushes. The use manual should be presented in Russian for our compatriots.

There are also options when on the Internet shops sell goods that do not have technical documentation. The link in this case happens to the fact that it is not necessary, since all the important information is already on the pages of the site. But keep in mind that from the point of view of the owner, this statement of the question is not justified. You may not always have a PC or a smartphone with an Internet connection at hand to clarify a particular issue that pops up as you use an electrical appliance.

Electric planer motor power

The indicator is important. It indicates what the capabilities of the instrument are. The higher the value, the better its performance will be. If this is an engine with a power of 1.5-2.3 kW, then this is a professional version, in this case the knives will be 100 mm in width or more. But for summer cottage use, 500-1000 kW will be enough.

When choosing, take into account such parameters as the use of different types of wood for processing. If it is a soft surface, then the power parameter will be different. But for oak, hornbeam and maple, a higher indicator is required. In the furniture industry, materials are used based on heavy wood species, all of which have high strength and decorative value.

If the planer has only 1 knife, then it will be very acceptable in terms of energy savings. The design of the knife shaft will be lightweight, which will also allow the use of electric motors, whose power indicators are much lower, but the performance of the tool will not be affected at all.

Knife shaft rotation speed

The electric planer has its own specifics, it lies in the fact that the higher the speed of rotation of the knives, the better and smoother it will be possible to process the surface of the workpiece made of wood. For this reason, do not underestimate this indicator. The minimum allowable speed will be 10,000 revolutions per minute or more.

If this is a rough type of processing, then the speed can be 12-13,000 revolutions per minute. It is possible to achieve a perfectly smooth surface of the array if the indicator is 15-18000 revolutions per minute. Pay attention to the fact that in some devices, when the load increases, it is possible to reduce the shaft speed. This will inevitably affect the quality of processing. For this reason, some models will have a speed support system available. For example, this is a tool from Makita model KR 0810 C. They manage to plan at the same speed level, while the loads can be both small and large. Moreover, this system is able to provide a safety option to the electric motor, which will not suffer from overheating.

Planing depth of electric planer

This parameter should be understood as the maximum chip thickness that can be removed with a plane in 1 pass. The higher the indicator, the better and faster you can process the surface of the array. Planing adjustment is possible by moving the movable part of the platform in relation to the stationary part.Displacements in the standard are possible 0-4 mm.

Regulation is carried out by means of the front handle, which must be turned around the axis. There is a graduated scale on the case. In accordance with it, it is possible to set the desired depth for immersing the knives into the material. The adjustment step will be 0.1-0.5 mm. In practice, planers in zero position start the planing process. Consider this fact while working in order to make corrections if it is important to maintain the indicated depth.

Planing width

The processing speed will depend on this indicator. If the board is 10 cm wide, then it can be leveled at a time with a knife 100-110 mm. If the indicator is 75-82 mm, then you will need to walk 2 times, at least. However, keep in mind that in the second example, the quality will be much worse. For this reason, the choice of 2 tools with different planing widths will be based on this parameter. Experts recommend giving preference to the option that is larger in width.

The size of the knives can be up to 350 mm in the case of professional planers. The devices are used only in production. In everyday life, the dimensions are 82-110 mm.

Tool weight

The parameter is equally important. If the instrument is very heavy, then working with it does not require physical exertion. Under its own weight, it presses the sole plane against the part, removing small vibrations and a number of vibrations. In this case, the user should only be careful to direct him in the right direction. The device will do the rest on its own.

But if the weight of the plane is very high, then during the work you may encounter inconvenience. For a home look, a weight of 3-4.5 kg is characteristic, but in the case of professional devices, it is several times higher.

Price question: how much does a good electric plane cost

If you need to process a large surface, then the cost of the device can be 12-26,000 rubles. A practical device for the production of frames and windows will cost 6-10,000 rubles. Options for a summer residence can be bought for 2-6000 rubles, but models with high power, which are able to cope with solid wood, sometimes cost more than 100,000 rubles.

Additional structural elements

Here it is worth identifying such useful options as:

Soft start system. It is able to increase the price of the device, but its useful life will be much higher. The acceleration of the engines due to it is smooth, the speed picks up speed in 3-5 seconds. This ensures minimal wear on parts. It is useful in cases where a voltage surge can cause a powerful blow to the gearbox or transmission belt.

Ventilation pipe. The 2-sided ventilation duct completes the chip evacuation system, to which a dust bag or vacuum cleaner is attached. As a rule, its exit is directed to the right side. It is designed for many people to be right-handed. But there are also those models that provide for a branch pipe outlet to the left side. No exception options on both sides at the same time. This solution is suitable for left-handed people, as well as when working on the right is not always convenient.

Also among the additional elements is an electrodynamic brake, a support system and a handle.