Glue guns are used for industrial and household purposes. They are popular among builders and needlewomen, DIYers and professional designers. Thanks to them, it is possible to easily glue materials that even the latest adhesives cannot cope with. The pistol is an irreplaceable assistant in the complex process of decorating with the use of minor details. He helps to prepare an original gift with his own hand, glue the bag strap or seal the seams. To know how to choose a glue gun, you need to familiarize yourself with the basic parameters, advantages and disadvantages.

Content

The device of a hot glue gun and how it works

The easier it is to assemble the fixture, the more durable it is. Such products comply with this rule - there is a minimum number of components inside that differ in increased strength and, with proper use, are protected to the maximum from possible breakage.

The shape of the device fully justifies its own name - it contains a handle that holds it in the process of operation and a barrel where the main components of the device are located.

In the area where the trigger is located in an ordinary product, there is a hole for the rod in this device. If they are inserted into the body, then they go through the sleeve into the heating chamber, a heating element is attached to it. The section of the rod that penetrates here will melt to a liquid state, and when its solid part is then fed into the chamber, an excessive pressure will be created. Because of this, the adhesive will be pushed out through the nozzle attached to the gun barrel.

Structurally, the device will consist of the following components:

- Glue stick.

- Feeder.

- Coupling.

- Network wire.

- The trigger.

- Melting chamber.

- Nozzle.

Housing

2 functions are performed at once: all accessories are held and acts as a stand to support the device in the required position. When the mass in the melting chamber has melted, the device should not be held with its nose up for a long period of time. In addition, it is not recommended to lay the turned on gun on its side, since this causes significant overheating of the body and damage to the product.

To leave the device in the required position at the bottom of the handle, a special site is often made on which it is installed. In front of the muzzle, a folding stand made of plastic or wire is fixed. The body has 3 points of support in order to firmly fix the device in the required position (1 in the handle and 2 on the stand).

Since the device contains parts that heat up significantly during operation, the body is made of hard plastic with poor thermal conductivity. In addition, such materials are characterized by insignificant weight, so the total weight of the product will rarely exceed 300 g.

The pistol grip is basically no different from the others - often, in addition to the passing wire and the trigger, there are no other elements in it. For the convenience of using the gun, anti-slip rubber pads are attached outside.

Feeder

The rod will be in contact with the annular pusher - a ring made of plastic or metal. If a lever acts on it, the ring will rotate slightly in the vertical plane, as a result of which the rod will be gripped and pulled behind it to the heating chamber.

An effort will be created by the carousel or slide trigger (movement is carried out around the axis or along the barrel), transmitted to the ring using a lever. Often, the last element will be the weakest link in the fixture, as novice users are pushing the trigger too hard, "squeezing out" a lot of glue.

If the user does not know which fixture to purchase, it should be taken into account that the ring is problematic when it is made for the corresponding rod size. In view of this, even with a slight deviation, the rod with force passes through the ring or slips inside it.

Guide clutch

It is a rubber tube: one end is put on the melting chamber, and a glue stick is put into the second end. This part has 2 main options:

- Will hold a solid rod, and therefore prevents the outflow of the liquid mass into the body of the product.

- It is considered a temperature bridge - if the glue stick was brought directly inside the heat chamber, it would melt due to heat transfer even during the idle period during operation.

Despite the fact that the coupling is made of heat-resistant rubber, it must be taken into account that it is one of the weakest parts of the device. When the mechanism is somewhat overheated, the clutch can be damaged by an attempt to turn the rod or pull it out in the opposite direction.

When various rods are used, in order to replace them, it is optimal to cut off the section that has already entered the inside of the coupling, put a new rod.

Heating chamber

In fact, it is a metal tube where the heating element is fixed. Different devices use different variations of this unit, for example, 2 or more heaters are installed, heating the rod in different places, and over time from the beginning of the tube to the outlet hole.

The heating unit determines the power of the thermal gun itself. The larger the chamber capacity, the larger the part of the rod that heats up.

Despite what is considered a key working part, it is often considered the most durable - with proper use of the gun, there is virtually no heater breakdown.

Nozzle

The main purpose of such a part will be to give the necessary shape to the glue and its dosage. Taking into account the category and price of the device, a direct-flow nozzle or with a valve is used. In the first situation, it will maintain the required thickness of the glue, and its dosage is carried out by the feed mechanism. The disadvantage of such a solution will be certain losses of the adhesive mass, since when a certain level of fluidity is reached, the glue will flow out.

When the nozzle has a valve, a spring-loaded ball is placed inside, closing the outlet with adhesive until excessive pressure is created by the trigger to unblock the channel. As an additional protective measure, the ball will not completely block the outlet opening - when the working chamber overheats and the glue becomes too fluid, its excess will be led out.

As a result, when working with the device, you need to use a stand where excess glue is collected.

The nozzle is made of metal, however, it is covered with a protective cover on the outside, which prevents possible burns during careless contact with it. When the nozzle is removable, the gun is equipped with several nozzles - this will make it possible to obtain a layer of glue of different shapes. In addition, standard auxiliary nozzles are available, but with an elongated nose, which simplifies access to difficult-to-reach areas.

Attachment to the device is carried out using a threaded connection, however, it is possible to unscrew the old nozzle only when the heat chamber is warmed up - otherwise the replacement of the part will be impossible due to the glue frozen in the middle.

How to use a glue gun

The prototype of the current glue devices is considered to be a device invented by G. Green, which was supposed to be a tool for quick gluing of furniture elements. His device was quite massive, liquid glue was used for work. However, a significant breakthrough was the application technology itself, which makes it possible to obtain an even seam, characterized by significant mechanical reliability and flexibility.

When it became possible to use a solid glue stick and the gun became quite compact, it became extremely popular. It is much easier to list the situations where it was impossible to use - fixing elements that heat up during operation (capable of softening the glue). In addition, the adhesive mass will not set properly on concrete, plaster and certain types of polyethylene, since they are susceptible to heat (special skills are required to work with them).

The operation of the device in question is practically unlimited: furniture makers were among the first to appreciate its functionality, builders use it to glue communication elements, model designers, designers consider it a universal tool. In addition to virtually immediate gluing of elements, using this gun it is possible to obtain polyurethane figures or patterns, make paintings or create prints on a postcard or invitation.

As a result, the gun in question is actually a versatile glue, but without the harsh odor. Able to fully harden for 2 minutes, gluing together wood, paper, leather, fabric, plastic, rubber, metal, ceramics in various combinations. In addition, you need to remember about the key recommendation for using each glue - the surface should be cleaned and degreased before using it.

Glue Gun Selection Options

In the process of choosing the necessary thermal gun for the purpose of construction work or handicraft, it is necessary to focus on the key parameters of the device.

Power

The rate at which the glue melts in the heat chamber of the device will depend on the amount of electricity consumed by the heating element. For professional tools, the power varies within 350-500 W, for semi-professional - 150-200 W, for household - 30-150 W. Products from popular manufacturers, also used in prof. and construction activities have a power of approximately 200 watts.

Performance

This indicator of the device under consideration is considered to be the mass of the adhesive melt exiting the nozzle for a specific period of time. Will vary based on the functionality of the heating element and the size of the glue stick used in operation. In a professional tool, rods up to 1.2 cm in diameter can be used, in a household tool - up to 0.8 cm.

The productivity of a professional product (no more than 30 g per minute) is several times higher than that in an amateur device of low power (5-10 g per minute).

Melt operating temperature

This parameter needs to be emphasized when it is envisaged to use a thermal gun during operation with a material that is susceptible to increased temperature indicators. For them, low-temperature glue special rods are used, the melting temperature is 105 degrees, and the device must function in a similar mode.

For the rest of the materials, rods with a melting temperature in the range of 170-200 degrees are used; for functioning with them, an appropriate thermo gun is used.

Some of the devices are capable of functioning in different temperature regimes, which will make it possible to use them for work with a wide range of materials.

Food

The developers offer the following types of thermal guns with different power supplies:

- From the mains.

- On the battery.

- Semi-autonomous - the assembly of part of the devices will make it possible to remove the power cable after warming up the heat chamber, which will make it possible to use the gun without a cord for a quarter of an hour, while the heat inside the chamber remains. Using a gun without a wire will make it possible to glue the elements or seal the seams in areas that are far from the electrical network, simplify painstaking work that requires significant accuracy.

Temperature regulation

It is an auxiliary option, which is equipped with a large number of products from the most popular developers. Comfortable during prolonged use of the thermo gun during the working day. A special switch will put the device into standby mode or turn it off during prolonged inactivity.

Auto adjustment of temperature indicators

Certain fixtures use the automatic temperature control option. A temperature indicator is installed on the heat chamber, due to which the regulation takes place in automatic mode. In the process of starting the heating of the heating element to the maximum, upon completion of heating and reaching the necessary indicators, the usual mode will turn on to maintain the temperature.

Glue stick diameter

Professional and semi-professional products of popular manufacturers are provided for glue sticks with a diameter of 0.7 and 1.1 cm. Usually, developers will take into account deviations and the range of indicators is indicated in technical documents, and not exact data: 0.7-0.8 cm and 1 , 1-1.2 cm.

The presence of a stand in the complete set

When the device was purchased for permanent use, it is possible to see the product, which will include a special stand. It is comfortable to place the device in it during those time intervals when it is not used. This is convenient and increases safety during operation.

Auxiliary options for comfortable operation

When the technical parameters of the device determine the quality of functioning, then there are certain auxiliary functions that directly affect the convenience of using the gun. They should also be emphasized, in particular when the device is purchased for permanent use:

- Ready indication. If the melting chamber reaches the rated temperature, the LED on the gun body will light up. The option will extend the service life of the device, since the consumer does not squeeze out the non-melted adhesive mass from the thermo-gun by applying force to the feeder.

- Lighting. It is an option that is not useful in all cases, but sooner or later, its presence will greatly help.

- Observation window. There are virtually every device - budget and expensive. It is useful in those situations when it is required to replace a long rod or to control how the short one will go into the thermoblock so as not to harm the coupling.

- Stand.Since the gun is in standby mode with the nozzle downwards, the presence of a folding stand is necessary. It is another matter that not in every device such a detail will ensure the proper stability of the pistol, therefore it is optimal to focus on it during the acquisition.

- Set. Much will depend on the developer, who is able to offer a branded case, rods for different needs, a heat-resistant mat from which it is easy to clean the flowing glue in combination with the device.

Since a gun is a fairly simple device, in fact, slightly more difficult than a soldering iron, with proper use, even a budget device will last an extremely long period, even when the device is of a not very popular brand. Even well-known manufacturers can produce budget products with protective electronics and other accessories - you just need to choose which device is best suited to the needs of the consumer.

The best manufacturers of thermal guns - which company to choose

Glue guns are included in the range by a large number of manufacturers who specialize in the production of electrical tools for construction and renovation purposes. Products from such manufacturers have proven themselves from the best side:

- Bosch.

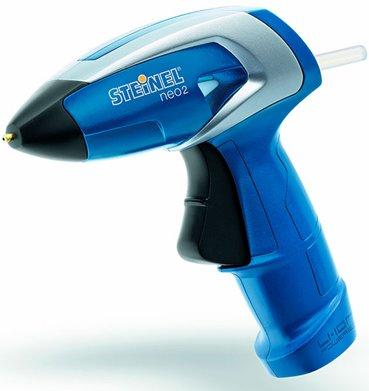

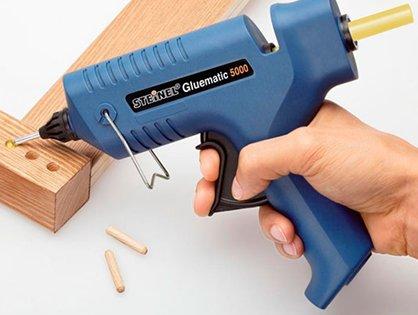

- Steinel.

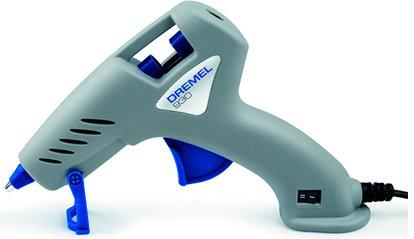

- Dremel.

- Bison.

- Kolner.

The developers include in their own assortment not only pistols that are designed for professional use, but also for home use.

Types of hot melt glue guns

The areas of use of the considered devices are quite diverse. They are used in construction, radio amateurs, in design, florists.

Taking into account the type of activity where the device is used, its power and performance characteristics, the device is divided into:

- Professional (for repair and construction);

- Amateur (for creative purposes, needlework and other household use). It has a lower cost, it is used periodically, because the working resource will be inferior to a professional product.

Professional

The gun, which is intended for professional activities of specialists in the field of repair and construction work. Designed for long-term use throughout the day. The device usually has an automatic glue stick feed. Auto feed is required for regular operation of the thermo gun.

Pros:

- significant power (300-500 kW) and increased productivity (25-30 g of glue melt per minute), the ability to carry out significant amounts of work in the shortest possible time;

- universal application - sealing construction seams in hard-to-reach areas, quick bonding of a hard surface, installation work;

- most of the products are equipped with several types of nozzles in order to carry out a specific type of work: universal, long (in order to process hard-to-reach areas), wide (in order to quickly fill significant gaps and surfaces with an adhesive mass);

- a long period of use due to the increased quality of the components that are part of the thermal gun.

Minuses:

- overpriced.

Rechargeable

Intended for home, work in a household workshop, for creativity and needlework. The device is powered by a battery.

Pros:

- there is no network cable, which will simplify the operation with small parts, make it extremely comfortable to work with small elements (with the power cord it is possible to accidentally throw off the container with jewelry);

- it is possible to use the device away from power sources.

Minuses:

- need to be recharged periodically.

Pneumatic

The contemplated fixture will apply the melted adhesive mass as a spray due to pneumatic delivery.Designed to function with materials that are sensitive to elevated temperatures, including foamed materials, their top layer is prone to deformation when exposed to high temperatures.

Pros:

- the glue will be applied in small drops without harming the area to be treated.

Minuses:

- larger dimensions compared to ordinary products.

For needlework

Handicraft pistol, used mainly for creative purposes. The device in question is used to decorate and make souvenirs. Its characteristic feature is considered to be low temperature indicators, which make it possible to use the device when working with material that requires careful handling.

Pros:

- accurate dosing of the adhesive mass;

- it is possible to adjust the adhesive composition in order to fix small elements (rhinestones, beads);

- glue flows quickly.

Minuses:

- poor performance.

Which glue gun to choose

Before choosing a device, it is necessary to decide for what purpose the device is required and for what task it is used. To know which device is better to buy, you should familiarize yourself with the recommendations for choosing a device, taking into account the tasks being performed:

- Professional. Has a power of 300 W and a productivity of 20 g per minute - it seals construction joints, installation of building elements.

- Rechargeable. It has power ratings up to 200 W - for the purpose of carrying out work at a distance from the power source.

- Low-temperature (glue temperature indicators no more than 105 degrees) - used for creative purposes using a material that is sensitive to high temperature indicators: paper, fabric, etc.

- A gun that operates in certain temperature modes - for the purpose of working with a wide range of materials, including delicate ones.

- A thermostatic gun with automatic power control - it will be comfortable in operating mode if the device is used periodically, and some pauses will follow between applying the adhesive mass to the material.

Hot glue gun cost

The cost of a heat gun will depend on the brand, the country of the developer and technical parameters. The price range is quite extensive, it is possible to purchase a budgetary device for 300 rubles. or a professional device, the cost of which will be over 5,000 rubles. Price for network glue guns of different power:

- Up to 50 W - in the range of 250-1000 r.

- 51-100 W - within 350-2000 p.

- 101-200 W - in the range of 500-4600 p.

- 201-300 W - within 5500-6800 p.

- 301-500 W - in the range of 3400-7300 p.

Often they ask themselves which glue gun is the best to choose. To find out how to purchase a quality product, you should read these recommendations.