Man's love for construction arose together with man himself. Having begun to build primitive dwellings from rough pieces of rough stone, man gradually improved in his skill as a creator, using more and more advanced and perfect technologies for creation, an ever wider range of tools that became more and more complicated with each era.

At present, it is no longer enough for the human creativity to just create something; you need to bring it into an ideal form: smooth the corners, level the work surface. That is why a person uses special devices - grinders. The best grinders in 2020 are not only high-quality tools with great functionality, but also an excellent help in the work of any master, as they can successfully process both dense concrete and soft wood.

Content

What is a sander?

The grinder is a special hand-held tool with which you can level and smooth the surface of wood, concrete, plaster and many other materials that, in principle, can be processed. It is one of the most common tools in home and industrial construction and has gained popularity for its reliability, quality and versatility.

Many craftsmen use the grinder as a multifunctional home tool that allows you to process the surface of various materials, sharpen knives and axes, cut material, grind holes, etc.

Types of grinders

There are a large number of types of this hand-held power tool, however, from the whole variety, several typical models can be distinguished, which are basic for further development.

There are usually 19 types of grinders:

- Corner;

- Straight;

- Horizontal;

- Tape;

- Vibrating;

- Eccentric (orbital);

- Planetary;

- Brush;

- Mosaic;

- Deltoid;

- Drum;

- Polishing;

- Multifunctional;

- For walls and ceilings;

- Ultrasonic;

- Mini;

- Stationary;

- Roller;

- For pipes.

The differences mainly relate to the design of the grinder, as well as the method of surface treatment of the material. Of all this variety, two main types deserve attention - belt and eccentric sanders.

- Tape... The design of this type of tool is based on a mechanism that scrolls a tape of sandpaper or any other material for grinding at high speed. Depending on the speed and intensity of the mechanism, the structure of the effect of the tape on the material also changes. The most common type of grinder and the most convenient for large surfaces.

- Eccentric... It differs from the tape only in that the processing surface moves in a circle, with an increase in the speed and intensity of material processing. A less common type of grinder, which, however, has a number of advantages, including easy and high-quality processing of small products and small parts.

Criterias of choice

There are several important factors that directly affect the choice of a particular model of a grinder. All these factors are important and depend only on the purpose of purchasing the instrument. Depending on the purpose for which you need the tool, you should pay attention to a number of criteria. If you plan to process a large amount of material, then you should give preference to industrial models, rough, with high productivity. If you are interested in a device for processing small surfaces, working with fragile materials or grinding, then pay attention to small and budget machines, with high precision and smooth processing.

- Power. The area of the surface treated by it, and its reliability, and productivity depends on the device's power. Typically, high-powered machines are used for construction and industrial work in large buildings, while low-power models are used for sanding furniture, jambs, baseboards and various other decorative and design work.

- Customization. The more the unit has options for customization, the more types of work it can perform, the more various types of material processing it is subject to. It is worth paying attention to models with a wide range of settings if you want to work with furniture, do apartment renovations or decorate buildings. Conversely, opt for rough, non-customizable models if you plan to process wood on an industrial scale.

- Functions. The functional variety of the machine is just as important to the craftsman as the other characteristics. It is worth realizing that a machine with a large number of functions can bring more benefits to the household, while a machine with specialized settings is suitable only for those who work in a specific niche.

- Material type. An important feature of each machine is the list of materials with which it is capable of working. If you are looking for a broad-based machine, choose a model that sands concrete, iron, plastic and wood with ease. If you need a highly specialized unit for woodworking, then you should choose a machine specially designed to work with this particular type of material and having all the settings for comfortable and efficient woodworking.

- Types of processing. The more functions for material processing your chosen machine has, the more profitable it is, the more different works you can perform. The range of application of the device is significantly expanding, because you can equally successfully process a tabletop and immediately sharpen an ax or knife on this device.

Which is better?

There is no need to guess which of the grinding machines is better directly in practical work. Different types of devices are designed specifically for different types of work, and there is no need to single out any one model as the best. There are several flagship models in each class of instruments, which are the most reliable and high quality.

The ranking of the best grinders of 2020 is presented in this article.

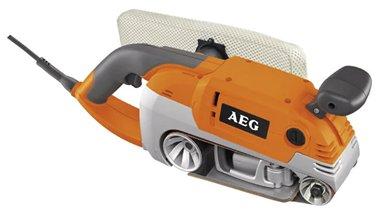

"AEGHBS 1000E"

The finest wood grinder, one of the most reliable models produced in the United States of America. The unit compares favorably with competitors with a large number of add-ons and built-in functions, as well as rich possibilities for advanced customization.

The device is started using a "soft start", enters into operation without a shock wave, gradually interacting with the material and leaving no gross damage in its texture.

In addition to this function, in the settings of the machine, you can adjust the processing speed of the material, the intensity of pressing the processing surface, or transfer the device to offline operation. The latter function is possible only when using the machine as a stationary machine fixed on a workbench.

The weight of the device allows the machine to press tightly against the material being processed and minimizes recoil during operation. The master only needs to direct the device in the required direction. Built-in overheating protection allows you to work for a long time.

Advantages:

- High performance;

- Performance;

- Resistance to long-term loads;

- Wide range of grinding options;

- Automatic operation function;

- Optimal weight;

- Smooth entry into the processing process;

- Adheres tightly to the surface of the material;

- Affordable price.

Disadvantages:

- Not quite high-quality dust removal;

- Unreliable drive belt.

"BORT BBS-801N 93728007"

The best small class machine for all types of surfaces. Refers to the type of hand tool. Very practical to work with and very popular with home builders.

Due to its small size, the unit is not configured to process a large amount of material, however, it copes “perfectly well” with small tasks such as grinding timber or finished wood products, for example, handrails or stairs.

Usually this model is used for making and assembling handcrafted furniture. The machine is equipped with a wide variety of working functions and the ability to fine-tune the tool. In addition to choosing the speed and intensity of processing, you can adjust the direction of grinding, the tension force of the sanding paper or choose the structure of the effect on the surface to be treated. Covered with thick and soft rubber, the housing significantly softens the recoil during intensive work.

All indicators and buttons are located on the surface of the device in the most visible place for the master.

Advantages:

- No need to hold the “Start” button - the built-in blocker easily holds it during intensive work;

- Sophisticated design that provides convenient and comfortable work with the device;

- Affordable price;

- A well-designed dust collector that leaves no dust or crumbs on the material itself or around the workplace.

- The ability to control the speed of the process;

- There is no difficulty in replacing the sanding belt.

Disadvantages:

- Sometimes the tool cover falls off, as it has no special fasteners;

- The dust is discharged to the left, towards the master, which is extremely inconvenient for right-handed workers.

"Makita 9910"

The best professional-grade eccentric sander. A quality tool from a reliable manufacturer that has firmly established itself in the construction tool market.

The model is distinguished by a carefully thought-out balancing of all nodes and the possibility of detailed adjustment and gaining full control over the material processing process.

The comfortable body is made of thick industrial plastic, all handles and buttons are covered with soft rubber, so that the tool "merges" with the hand, which provides a comfortable process.

The device comes with a special capacious bag for collecting dust, shavings and pieces of processed material.

The model is started using the "Start" button equipped with a "soft start" function.

It is quite simple to replace the sanding belt - it itself "jumps out" from the device by pressing a special button. The built-in balance prevents the model from following a curved path, which ensures uniform treatment of the entire material area.

Can be used for abrasive grinding.

Advantages:

- Easy to use, very convenient and reliable;

- Lightweight, which allows the master to work with one hand;

- High build quality;

- Resistant to long-term workflow;

- Reliably protected from moisture and dust;

- Frost resistant;

- Built-in balance;

- Ergonomic and comfortable body.

Disadvantages:

- Not powerful enough;

- There is no way to adjust the speed of the material processing.

"Black Decker KA 88"

A professional draw frame designed specifically for the processing of materials on an industrial scale. With this model, you can easily work with furniture boards, walls, parquet floors, plank floorboards and roofs of small log cabins.

The advantageous side of the machine is its strength and reliability: a simple design allows long-term work with coarse material, and setting the type of processing allows you to choose the degree of intensity of impact on it.

The body of the unit is made of durable refractory plastic, the tape holders are made of monolithic PCB and metal, and the handles are covered with soft rubber, which securely fixes the device in the hands of the master.

It is especially convenient to use this model when processing corner joints and hard-to-reach surfaces - the turning mechanism of the tape will allow you to get to them without much difficulty.

Also, the machine is equipped with a special protective mechanism that keeps it at a small distance from the edge of the work surface and does not allow cutting off a thicker layer of material than is necessary according to the settings.

The device is reliably protected from dust and moisture.

Advantages:

- Low weight;

- Long power cord;

- Euro plug for connecting to a European type network;

- The presence of an adapter for connecting to domestic-type sockets;

- Fits tightly to corner joints;

- Qualitatively processes not only the front side, but also the side surfaces;

- The abrasive belt can be adjusted in several ways at once;

- The body is made of impact-resistant plastic;

- Unpretentious in service and workflow;

- Low price;

- Long warranty period;

- Falls well;

- Resistant to deformation.

Disadvantages:

- The process of replacing electric brushes is complicated;

- The drive belt is quite narrow, non-standard, and difficult to find on sale.

Hitachi SB 8V2

An excellent Japanese-made machine for those who like to work in the field of decorating work surfaces. The model perfectly copes with furniture boards, tabletops, chair seats, various details of headsets and services. In addition to working with wood, the unit copes well with metal and plastic, and can also be used for grinding bricks, for example, when building a semicircular arch or removing a floating wall relief.

Many craftsmen use this model for "sanding" and roughing the surfaces of old products; the machine works cleanly, smoothly, without leaving streaks or potholes of various depths on the surface of the processed material.

The model has a large number of configuration methods, and can also operate in several modes, which can be switched using bright and noticeable rubber buttons. The machine body is made of solid polymer and reliably protects the engine.

Due to the special shape of the body, the machine can almost closely press against the treated side surface and work carefully with the coating.

Advantages:

- Powerful;

- Reliable;

- Can work with hard wood species (oak, beech, larch, birch);

- Equipped with a special branded dust collector that does not allow crumbs, shavings and sawdust to remain on the working surface;

- Has a wide range of settings;

- Several speed modes;

- Durable solid polymer housing;

- Low price.

Disadvantages:

- Lack of internal balancing;

- The machine sometimes "mows" slightly to one side;

- Quite heavy;

- It is inconvenient to handle vertically located surfaces, including ceilings.

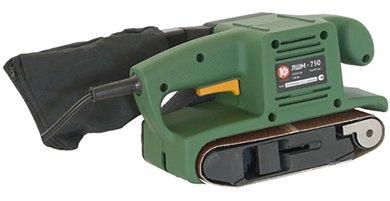

"Caliber LShM-750"

A standard domestically produced belt sander capable of sanding anything that has a surface. The product is a little rough and rustic, but extremely reliable and workable.

The powerful electric motor makes it easy to work with heavy surfaces and to rid the material of dried varnish, old paint, wood pile.

The body of the machine is made of hard industrial plastic, all buttons and control levers are molded from durable resin.

The model is very convenient when working with parquet, jambs and skirting boards.

Despite the reliability and ease of use. The model can grind the coating only in two high-speed modes of operation, and also has practically no settings.

The engine is reliably protected from overheating by a special internal cooling system; the body of the machine is waterproof and does not allow dust, moisture and dirt to enter the device. Also, the body is equipped with special fasteners that allow you to make a stationary machine out of the machine, fixing it on a workbench.

Advantages:

- A wide range of adjustment of the position of the abrasive belt;

- High power;

- Reliability;

- Handles hard wood species well;

- Can be used as an industrial machine tool;

- Small;

- Quite lightweight;

- Low price.

Disadvantages:

- Makes an unpleasant noise;

- Rough;

- Insufficiently elegant case design.

Bosch PBS 75 AE

Decent answer of the German manufacturer to the question "Which grinders are better?" This professional grade model is one of the best representatives of this type of construction tool.

Powerful, reliable, with a large number of modes and a wide range of settings, the machine is capable of working with absolutely any type of coating - from hardened concrete to delicate products from architectural plaster.

However, it is intended for processing material on an industrial scale.

The settings of the unit allow you to select several speed modes of material processing, the angle of inclination of the abrasive belt, the force and intensity of pressure on the material, as well as the area of the processed surface.

A wider belt is installed on BOSCH than on similar machines, which allows you to immediately process large volumetric surfaces, however, a very narrow strip of grinding material can be installed on the rollers, which will allow you to work with small and fragile products.

With all this, the weight of the machine is relatively small. The body is made of hard grades of polymer plastic, all handles are covered with an impressive layer of soft rubber. The machine mechanism is reliably protected by a special visor from dust, moisture and processing products. On the left side there is the possibility of connecting a dust collector with a built-in vacuum cleaner function.

Advantages:

- Reliable;

- Very powerful;

- Resistant to long-term heavy loads;

- Wide strip of abrasive material;

- Built-in "soft start" function;

- The ability to adjust the speed of rotation of the rollers;

- Possibility of adjusting the position of the tape;

- High quality;

- Reliable case;

- Built-in dust collector and vacuum cleaner;

- High performance;

- Coverage of an impressive area of the processed material.

Disadvantages:

- Inconvenient network cable;

- Air and dust are blown out towards the master.

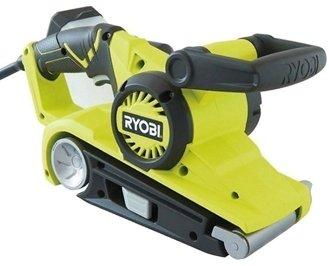

Ryobi EBS 800V

Small type grinder from Japanese manufacturer. It belongs to the class of professional tools and is very popular with furniture manufacturers. Easily handles fairly large surfaces such as furniture boards, chair backs, cabinet walls or shelves. It interacts successfully with all types of wood, including larch and beech.

It has a wide range of settings for processing speed, intensity of impact on the material, and there is also a function for adjusting the position of the belt relative to the bearing rollers.

A distinctive feature of this model is the ability to adjust the position of the handle, allowing the master to perform more complex technical tasks.

The body of the device is made of hard plastic and a textolite base, to which a mechanism is attached that holds the abrasive belt and a lever with which it can be easily changed.

The built-in motor is very reliable and can withstand heavy overloads during long and intensive work.

Some craftsmen successfully use this model for sharpening knives, axes and other types of tools with flat or round blades.

Advantages:

- Powerful;

- Reliable;

- Resistant to overload and lengthy workflow;

- Extremely high performance;

- Wide range of settings;

- Ability to sharpen cutting tools;

- Replaceable handle;

- Ergonomic solid polymer body;

- Textolite base;

- It can process wood, concrete, plastic, metal and other types of hard materials.

Disadvantages:

- The dust collector channel quickly deteriorates;

- Bearings must be constantly lubricated;

- Low oil level in the reservoir;

- Small tank capacity for special liquids.

"PATRIOT BS 810"

Woodworking machine for home construction. One of the best models in its class. Winner in the Best Belt Sanders category. A belt device specially designed for processing all types of wood. Despite its narrow specialization, the machine is very convenient to use and has a number of unique functions, such as drilling grooves of various thicknesses, processing sharp corners and incredibly fragile objects.

It is characterized by low pressure on the surface to be treated and the tight fit of the sanding belt directly to the material to be processed.

The engine of the machine is very reliable and powerful, which allows you to process large volumes of material for a long time without fear of overheating or motor failure.

The body of the device is made of thick and reliable industrial plastic that does not crack or deform from constant heating or prolonged exposure to high temperatures. You can safely leave the tool in direct sunlight. The power buttons and setting levers are made of organic plastic and will not break even after many years of use.

Advantages:

- Built-in locking mechanism against accidental activation;

- Powerful;

- High performance;

- Reliability;

- Strength;

- Overload resistance;

- Lightweight;

- Reliable protection from moisture and dust;

- Very reliable and durable;

- There is a function of easy replacement of abrasive material and electric brushes;

- The set includes an extension cord, a tool for servicing and repairing the machine;

- Large selection of settings and add-ons.

Disadvantages:

- Sometimes the machine does not have enough mass to work with horizontal surfaces;

- Not long enough cable;

- It is inconvenient to work with an extension cord.

"SturmBS 8511 U"

A classic of the construction processing industry from the legendary German manufacturer.

A classic for cutting tools from the legendary German manufacturer. One of the best professional-grade models designed for household work and industrial construction. Despite the "woody" orientation, it copes well with work on concrete, iron and plastic. Successfully grinds large surfaces with a complex relief structure and straightens even the most hopeless damage to the front side of the material.

It is usually used for cleaning parquet flooring from layers of household varnish, for cleaning metal sheets from rust and scale, as well as for peeling off bark from tree trunks and boards. In addition to household construction, it can perform the functions of industrial processing of materials.

Despite its amazing power, the machine can do fine, painstaking work like sanding plinths, plaster or giving walls a floating relief.

The body is made of durable plastic and covered with a thin layer of rubber, designed to protect the master from a possible short circuit. The insides of the machine are reliably protected from moisture, dust and dirt with a special cover.

The handles are made of plexiglass, have a comfortable shape and are rubberized for a secure grip.

The power and adjustment buttons are bright, clearly visible and made of a solid grade of polymer rubber.

The start button is equipped with an additional blocker, which allows you not to hold it during intensive work.

The engine is very reliable and designed for long-term operation without rest, it is resistant to overloads and overheating.

The machine has medium dimensions and is very convenient for transportation and manual work.

Advantages:

- Power;

- High performance;

- Quality;

- Rich range of settings;

- Several speed modes;

- Can be installed as a stationary machine for professional work;

- Low price;

- The kit includes several attachments, an extension cord, a spare cord, and several abrasive belts;

- Double fastening roller for tape;

- Reliability;

- Resistant to overload and long-term use.

Disadvantages:

- The frame interferes with the reliable fixation of the tape in the roller;

- There is no adapter for connecting to a vacuum cleaner.