There are many different types of industrial fans. All of them differ in power, build quality, pricing policy, purpose. The main task of such units is to independently circulate air in an enclosed space. They are applicable in industrial workshops, mines, premises where air flow or gas combustion is required.

Particular attention is paid to ventilation, cleaning and air circulation in industrial plants with a huge number of personnel. You can't do without such fans. How to choose the best industrial fan in 2020, what to look for when choosing and what models exist, more on this.

Content

Basic selection rules

Choosing a good industrial exhaust fan is not easy. A lot of important functions should be assigned to it. In addition to air circulation, it must efficiently and effectively clean it from combustion products, fumes, smoke, pungent odors, and other contaminants. Before buying, they get acquainted in detail and calculate all the necessary parameters. These include the temperature of the air flow, its speed, and static pressure indicators. Only with the correct calculations, the ventilation system will work accurately and efficiently.

The main types of industrial ventilation systems

There are several types of industrial fans. They differ in the way of installation, power and structure. For these reasons, the following types are distinguished:

- Industrial exhaust fan. It is designed to be used for supply and exhaust in a ventilation system. Such installations are quite easy to install indoors on the surface.

- Floor. It is installed on the floor, has wheels, the blade angle is adjustable.

- Wall. Installed on walls for ventilation and air purification, maintaining a certain temperature regime.

- Radial. It features a high level of efficiency and high power. Effectively eliminates smoke.

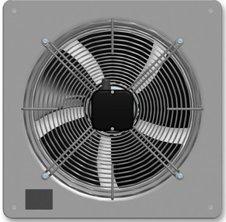

- The industrial axial fan is very versatile. Has a lightweight construction.

Varieties of industrial fans

This list contains models of the best industrial ventilation systems.

VSV 311-4 L1

This type is roof-top, characterized by vertical discharge of air pumped out of the room. In addition to good performance, it effectively saves space due to its compact dimensions, the air path is shortened. Equipped with high quality German engine. Due to curved blades, electricity is well saved, a high level of resistance to heavy loads is noted. Made of high quality steel.

Pros:

- high build quality, increased efficiency, endurance;

- made of high quality steel, protection against moisture and dust;

- reliable, long service life.

Minuses:

- not found.

AIR SC YWF4E-500B

Axial fan type, applicable in rooms with aggressive air. It may contain small amounts of dust. It is used in the inner and outer parts of the building. Equipped with protection against moisture and dust. It is regulated by an electronic system. The blades are made of high quality steel.

Pros:

- due to its simple design, it is convenient for installation and connection to electricity;

- the speed can be adjusted;

- the main components and the grille are included in the package.

Minuses:

- noisy, suitable for industrial use only.

CMFD 400

The industrial duct fan is used in mines or ventilation ducts. Works on an axial basis. Equipped with stationary direction blades. It has a high efficiency due to high-quality assembly and dynamic balancing. Made of high quality aluminum alloy.

Pros:

- high level of performance and power, energy efficient, high percentage of efficiency;

- the body is made of high quality aluminum, moisture resistance;

- very easy to maintain;

- reliable, long service life.

Minuses:

- not found.

WOKS 200

The axial fan is applicable in large rooms where uninterrupted air exchange is required. These include gyms, fitness centers, large hangars for business activities, warehouses and workshops, and others. There is a double-sided grille for protection. All parts are made of high quality steel. A weather-resistant coating is applied on top, the basis of which is powder enamel. The numbers and revolutions are regulated using an electronic panel.

Pros:

- the assembly is made of high quality parts and materials;

- applying a protective coating;

- in terms of noise indicators, it is medium;

- high percentage of efficiency, reliable and hardy.

Minuses:

- not found.

CMPT / 2-200

It is used in rooms with an aggressive environment. Effectively removes gases, combustion products, smoke, chemicals and harmful vapors. Equipped with a single-phase asynchronous motor, casing and impeller. Manufacturing material - high quality polymer. There is a special hole for drainage of condensate that forms during operation.

Pros:

- can be used in heavy smoke, made of high quality plastic;

- almost does not vibrate during operation;

- reliable, durable, high level of efficiency.

Minuses:

- not found.

WD630-CH-03-08

It is used for ventilation of industrial premises, gyms, utility warehouses. Differs in a very high level of quality. Country of origin Germany. German electric motor, high quality aluminum blades. Equipped with mounted thermal protection, automatic restart option.

Pros:

- high quality assembly, does not emit any extraneous sounds during operation;

- good balance of the assembly;

- effectively copes with the assigned tasks.

Minuses:

- not found.

CM 21.2H

The fan is professional. Works on a radial operating principle. Differs in work with mixtures of gas-air consistency of high temperature conditions. Suitable for air extraction in heating boilers operating on solid fuels, refrigeration plants, laboratories. Effectively protected from dust and moisture.

Pros:

- effective when working at high temperatures;

- can be used in conjunction with a solid fuel boiler;

- easy to maintain, no difficulties in use.

Minuses:

- works noisy, soundproofing may be required.

CMB / 4-200 / 80-0.25

The industrial snail fan is of the centrifugal type. An impeller is attached to the motor powered by electricity. The motor itself is attached to a prefabricated housing. The rotor is made of high quality galvanized steel. Due to the impeller bent towards the front, the dimensions are significantly reduced, and high efficiency is noted. Coated with a protective coating against corrosion.

Pros:

- high level of performance, one-piece construction;

- good protective coating against corrosion;

- all nodes are connected.

Minuses:

- not found.

Industrial ventilation systems can be of different types and varieties. All of them are distinguished by methods of installation, power and purpose.Before choosing what you need, they get acquainted in detail with the rules of selection, types and models of industrial fans.