Let the spray gun by its design principle seem simple, but the choice of the device is able to find many to a standstill. Until recently, the task was somewhat simpler, because there were only pneumatic devices on the market. Nowadays, electric spray guns have appeared, which are not devoid of both advantages and disadvantages. To understand which spray gun to choose and make the right decision, it is worth delving into the design features of the device, its principles of operation, and scope. It is important to imagine for what purpose you are buying a spray gun.

Content [Hide]

- 1 List of spray gun manufacturers: which brand to choose

- 2 Basic principles of operation of a pneumatic spray gun and design device

- 3 Varieties of spray guns

- 4 Choosing the right pneumatic spray gun

- 5 Paint application: technology features

- 6 Parameter of the nozzle diameter of the pneumatic type of spray gun

- 7 The main parameters to rely on when buying a spray gun

- 8 Compressor add-on accessories

- 9 Comparison of pneumatic and electric spray gun

List of spray gun manufacturers: which brand to give preference to

If you are looking for a durable and reliable device, we recommend that you pay attention to the proposals of famous brands that have been specializing in the production of equipment for professional use for several years. Today there are leaders recognized by specialists and consumers on the market who can offer really high-quality products.

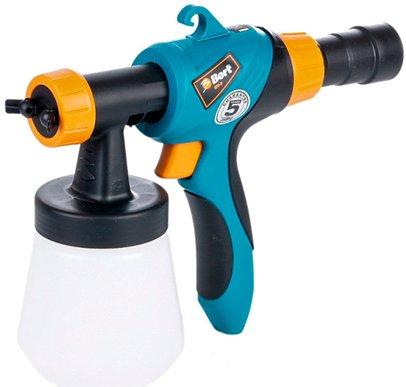

With the goal of deciding which spray gun to choose for painting a car, we suggest you pay attention to brands such as Walcom, Sata, Wagner, Devibiss and Bosh.

But keep in mind that the purchase will be more reliable if you still study the technical properties of the spray guns thoughtfully, delving deeper into the topic. Our article will become a real lifesaver for this purpose. Well, let's move on to the parameters of a successful purchase of a spray gun.

Basic principles of operation of a pneumatic spray gun and design device

Studying the question of how to choose a spray gun, you must first understand what this device is. Today, such designs are a compressor equipped with an electric motor and a receiver. The spray gun itself consists of a spray nozzle that resembles a gun. From the lower and upper parts there is a special tank, into which paint is added.

The receiver with the spray is connected to each other due to a rubber hose, which bends perfectly. Air is supplied through it under pressure. It is also worth noting that the sprayer delivers paint, breaking it into particles with a stream of compressed air. She exits the nozzle of the gun. The shape is made so that the flow of air and paint is not straight, but forms a torch that diverges to the sides in accordance with a certain angle.

In order for the structure to work without breakdowns, manufacturers perform component parts on the basis of high-quality materials.They are all matched exactly to each other. As a result, this is reflected in the final price of the product. It is for this reason that professionals use pneumatic spray gun designs.

Varieties of spray guns

Pneumatic view

These devices are produced, as a rule, on the basis of lightweight aluminum, which has durable characteristics. This is a high-quality device, although it is not always possible for it to distribute paintwork materials in an economical way over the desired surface. The emulsion carryover percentage in the mind of the model will vary 45-70 percent. The rest of the paint will be dispersed as a mist.

The main function is assigned to the compressor. It supplies compressed air to the structure of the gun itself and is able to create a pressure that will be equal to 0.7-2 bar. At the same time, it is important to note the gas consumption rates, which will be 150-1000 l / min.

Devices can have an external tank and a built-in one. In the first case, the paint capacity will be 25 liters, and in models for home use, all 600. But the built-in tank will have a volume of 0.5-2 liters. If this is a professional technique, then the spray gun has a high tank volume.

Speaking about the advantages, it is important to indicate the presence of a high speed of functioning and quality of painting. You can also use external tanks that have a solid volume. The work can be carried out with paints and varnishes. Anyway, the pneumatic type of the spray gun is as simple and convenient to use as possible.

As for the shortcomings, please keep in mind that this is a professional technique. At a cost, it is not cheap, and therefore, in the event of an acquisition, you should be prepared for a solid cost. It is also important to indicate the average percentage of paint loss at the exit.

Mechanical view

This is not the weakest member of the family. But the device does not have any particular exact parameters, nor does it differ in maximum speed during painting. But for the price, this is a completely acceptable option than other options. For this reason, ordinary people often use such options to carry out work related to whitewashing.

The principle of operation of mechanics corresponds to a simple pumping chamber. It is presented as a children's water pistol. You should pull the trigger several times to force air in. When the pressure reaches 0.4-0.6 MPa, the valve will open and paint will leave the device using a nozzle.

It should be noted that the construction is simple, the dyeing process is uniform. This does not require any special skills to do the job. The device is inexpensive for the price.

As for the disadvantages, please note that the spray gun must be manually pumped up on an ongoing basis. And the degree of dispersion of the suspension is really high.

Electric aerial view

Spraying is carried out not under compressed air pressure, but through the use of a pump. Electric spray gun can be used for home. Powered by 220 V. Devices are compact in size, easy to disassemble and assemble. This does not create problems during service, if necessary. All this allows you to create airflows that are popular with household masters.

By weight, the structure with an empty tank is 1.4-2.5 kilograms. The built-in container will hold approximately 1 liter of paint. Those. by weight, the spray gun will hold more comfortably. But keep in mind that the transfer quality in this case will be slightly lower than that of the pneumatic type. But in terms of power and performance properties, it is an irreplaceable option for home use.

As for the pluses, there are a lot of them. Let's name only the most important ones. It is worth mentioning the acceptable weight, portability, ease of maintenance, as well as the presence of a large selection of attachments that come with the kit. The performance figures are also encouraging, despite the affordability.

As for the disadvantages, the device works noisily, and therefore get ready for the hum. But the quality of painting will be lower than in the case of pneumatic sprayers.

Battery view

In fact, these are the same electrical models, but the work is carried out not from the mains, but taking into account the functioning of the battery charge. In accordance with the appearance, the spray gun is presented as a manual screwdriver. It is convenient and compact. The device can be additionally equipped with a tank with a capacity of 1-2 liters.

It is important to indicate that the power, as well as the performance indicator, will not differ from the characteristics of the electric type air vents.

The advantage is that the dimensions are very compact. The device is convenient to use, there are a lot of attachments, and the quality of painting is not bad, albeit not perfect.

As for the disadvantages, keep in mind that from time to time the device needs to be recharged, the painting quality is not above average, and the cost of the device is higher than that of the electric type.

Electric plunger (airless) type

In such models, the emulsion will be pushed out due to a special piston - a plunger. The quality of painting is not the best, but due to the absence of air blowing, the formation of "fog", as well as the consumption of the mixture will be noticeably reduced.

As a rule, an airless spray gun is a compact device that has a tank with a capacity of 0.8-1.2 liters. The feed rate in it will vary 0.3-30 l / min due to the type of equipment. But the main thing is that plunger devices are able to suck paint directly from a bucket or cans. This process takes place due to a special hose.

The advantages of the view are that the structures are convenient and easy to use, cleaning is not difficult, and performance is at the level. At the same time, paint consumption can be called economical. A big plus is that the devices are affordable.

Speaking of the cons, it is worth noting that the quality of the painting is not high, and the use excludes all other paints, except for synthetics and acrylic.

Choosing the right pneumatic spray gun

Quite often, one can hear disputes on the topic of what should be chosen initially - a compressor or a spray gun. There are a number of arguments that can be given, but the most correct decision depends on what kind of work you want to carry out. Choosing a spray gun, you can choose a compressor for it.

Paint application: technology features

The device can be supplied with one of the 3 available paint technologies. They all vary among themselves due to the operating pressure and the need for air, which is supplied by the compressor. The technology is reflected in the names of the spray guns. We are talking about HP, HVLP, LVLP. Please note that they all know how to cope with the lack of a device. This is the formation of "colorful fog", which is inherent in all spray guns. Its appearance is associated with a strong crushing of paint particles, which become excessively light in weight. Also, on the way from the nozzle of the gun to the surface to be painted, they can be inhibited by air, while remaining in it in the form of a suspension.

3 LVLP

The technology provides for low pressure and the same volume of air. Premium device with paint transfer rates up to 80 percent. The technology does not require a high-pressure air gun at the inlet, and a powerful compressor is also not required. The option that produces about 200 liters in 1 minute of work is also suitable.

It seems that with a lower air pressure, the operating speed will drop, but this does not happen with a large transfer ratio. The quality of painting in this case will be higher, since less control over the distance from the gun to the surface to be painted is required.

Let the LVLP spray gun be expensive, but such devices are irreplaceable when working with paints and varnishes of the premium segment.Let the ink savings be no higher than 5-10 percent when compared to HVLP, but with regular use the device will definitely be able to justify itself and quickly enough.

2 HVLP

The technology provides for low pressure and large air volume. The nozzle of the gun will be made so that the high pressure from the compressor is reduced at the outlet. Let the paint fly out at a lower speed, but the amount per unit of time will be greater. The airflow will be lower, allowing you to keep the gun closer to the paint surface that is being sprayed. During this time, the loss of paints and varnishes will be reduced, and the transfer coefficient will be more than 65 percent.

Such devices are more expensive than high pressure spray guns. But keep in mind that the paint savings will be as high as 15 percent. This will allow them to pay for themselves quickly enough.

1 HP

Provides high pressure. The technology is pertinent in devices that are inexpensive. She has many drawbacks, which are increasingly forced to abandon this type of device. But if your budget is limited, then it is likely that you will be happy with such a purchase.

The main advantage is that the device paints the surface as quickly as possible due to the use of a large air flow. But shortcomings are also tied up.

Note that a high percentage of paint that does not land will be more than 50-55 percent. It must be admitted that overspending is really noticeable in the field of application of paints and varnishes. Moreover, there is a high level of air pollution. More often it is necessary to buy paint, change respirators and protective suits. In general, this outfit is irreplaceable when working with this technology.

High air pressure will require skills in using such equipment. If, however, the nozzle of the gun is brought close to the surface to be painted, then the air flow will help the paint to swell, even if it has not yet frozen.

Even if the spray gun works in accordance with HP technology, its price is not high. There is a need to create high pressure and high air flow, and therefore a sufficiently powerful compressor is needed.

If we close our eyes to the question of economy, then high pressure spray guns are inexpensive. These are universal devices that are used in most cases for paintwork.

Parameter of the nozzle diameter of the pneumatic type of spray gun

The density of the paint, its properties of viscosity and graininess will depend on the nozzle whose diameter you will use. Holes can range from 0.8-7mm. The size will depend on the size of the part you are going to paint. For example, if this is a carriage building, then first of all it is important that the spray gun can apply paint on a large area in 1 pass.

A lot of manufacturers produce spray guns equipped with replaceable nozzles. They are equipped with monolithic tips for 1 time, which is not uncommon. But here we will note that for a professional device for painting, an additional nozzle for the nozzle may not be required at all.

The diameter of the nozzles of professional devices should be selected in view of the paints with which you plan to work, as well as the dimensions of the parts that are to be painted. For the needs of a household plan, it is recommended to work with nozzles with nozzles with a diameter of 1.5 mm. This is an option that is suitable for a number of types of paints and varnishes. They represent a rational compromise between speed and quality of painting work.

As a result, if a set of nozzles of an additional type does not affect the price, then you should not refuse to expand the optionality. Otherwise, think about how much such options will be in demand in your practice.

Tank for paint

This is an obligatory part of the design, but few people think about it when choosing a spray gun. Let it depend on the material on the basis of which the tank is made, how convenient it is to work with it.

The materials are different. It can be metal or plastic. The weight and transparency of the cistern play a big role. The thing is that the first will determine how quickly the hand gets tired while working, but the second will control the level of paint that remains. In accordance with these indicators, plastic tanks remain the leader. Sellers note that the percentage of sales on them is high. But the metal also found its consumers. These are cases when increased requirements are imposed on the strength of the device.

The location of the tank can be top or bottom. This is equally important. If the tank is on top, then the paint is fed into the gun by gravity, and at the bottom it is sucked in when the air compressor is taken into account. Placing from different parts of the structure will not improve the quality of the staining performed, and therefore you should rely solely on how convenient it is for you to work with this or that option.

When the tank is at the top, the spray gun has a better weight distribution. But in cases with interruptions in work, it is better to think about where to put it. But when the tank is located from the bottom, it forms a stand. Plus, if there is a need to paint the walls near the ceiling often enough, then the spray gun can be safely raised higher.

Availability of adjustments

All manufacturers resort to the decision to equip devices with different adjustment methods. Due to this, their number can be completely different. There are no regulations on this account.

Be sure to install the needle travel adjuster. It allows you to determine the amount of paint that is supplied to the device. The air supply restrictor, shape or size of the paint torch can also be set. Additional adjustments are not excluded that affect the painting process in different ways, due to the use of paints and varnishes.

The main parameters to rely on when buying a spray gun

If the properties of the gun of the device are capable of affecting the quality level of painting, then the compressor will depend on how the gun receives the right amount of air, which has the required pressure. Also how long he manages to work without stopping.

Receiver volume

The main task of the receiver is to equalize the outgoing air flow. Due to the pump, it is gradually supplied in the form of jolts. Building up the right pressure is also his responsibility. There is a directly proportional relationship. It lies in the fact that the larger the volumetric parameter of the receiver, the more stable the air flow will be, and the compressor motor will rest longer until the pressure is reduced. On the other hand, a large receiver will take longer to gain the desired pressure.

For using spray guns at home, a receiver may be suitable, the volume of which will be 25-50 liters. This is the golden mean when you choose between compactness, performance and switching frequency for trouble-free operation. Those. this is quite enough to carry out painting work on a professional basis.

100-500 liters will be required if a production line is to be provided. If you have doubts about choosing a receiver, or if you need a margin for the future, then pay attention to the connector that is needed to connect an additional receiver plan. Often, it is installed in cases of need to increase the working volume.

Engine power properties

A number of budgetary and semi-professional compressors are equipped with electric motors, the power indicators in this case will be 1.3 kW. In this case, the volume of the receiver will be no more than 50 liters, which is quite enough to support up to 6 bar of working pressure.In the store, you can see 2 engines, which, according to external data, seem to be the same, but if you look closely, their power indicators are different. Of course, the hand will reach for the device with 2 kW, rather than 1.3, but do not think that due to the quality of the winding, the engine power will be increased. As a rule, the more powerful the device is in its properties, the more solid its dimensions.

Look at the compressor drifts. If they are the same size, then most likely you have 2 similar devices in front of you. Immediately, power properties are used as a marketing ploy from the manufacturer. This is due to the fact that the power will not have a relationship to the air injection rate. The size of the piston and the number of shaft revolutions per minute affect. If the pistons are the same, then in order to increase the air injection rate, it will be necessary to remember that a large number of revolutions is proportional to the rapid wear of the piston group and bearings.

In general, there is another way to deal with this situation. It is necessary to bleed air from the receivers and measure the time it will take to fill them. In this case, all the secret will become clear and you will understand which device will suit you best.

Air pressure

All receivers have a pressure switch. It allows you to set the desired parameters that allow you to turn the motors on and off. In compressors used for painting, the lower bar is often 6 bar, while the upper one is 8 bar. This means that if there is less than 6 bar in the receiver, then the engine will turn on and pump air until it reaches 8 bar. The need for more pressure will be in the case when the compressors are used in production.

Performance properties

As with the engine power rating, this is a marketing gimmick. Pay attention to this parameter. This is due to the fact that there are 2 types of compressor performance - what it pumps into the receiver and the volume that comes out with a pistol.

The characteristics may indicate the amount of air that is driven by the pump, but at the same time manufacturers hide what losses are observed in the case of compression. They can go up to 35 percent. That is, to get the real figure, you need to multiply this parameter in the passport by 0.65.

If the compressor has lower performance properties, then, probably, the pressure will not be enough for the pistol, and therefore long pauses in its operation associated with the pumping of air will be recorded. Or there is a possibility that the engine will run without any interruption. This will accelerate its wear, without having the right to warranty repairs.

As a result, we can say that this parameter is one of the most important, and therefore take it into account and select with a margin, given that in addition to the operation of the spray gun, there is also the possibility of connecting an additional type of equipment.

Compressor add-on accessories

Some additional options still need to be in the device, but there are also those that will depend only on the decision of the manufacturer. In the first case, a protection valve can be designated. It takes over the function of bleeding off excess air in cases of failure of the pressure switch. A circuit breaker is also important, which is able to turn off the engine if an overload is observed.

The compressor can be additionally equipped with a pressure regulator, air filters and a pressure gauge. The mass of the engine with the receiver is large, and therefore look at whether there are wheels, what is the ergonomics. Those. all of this will affect how convenient it is to move the compressor from one place to another.

Here you can end with the fact that the choice of the compressor should be carried out taking into account the calculations that need to be done correctly. As a result of a mistake, you can buy a device that will disappoint you in practice.

Paint type

The choice will depend on the pump, which is responsible for the supply of paints and varnishes.Many electric spray guns are versatile. But keep in mind that there are different types that can be used for work, but with water-soluble formulations.

Extension gun

This is the option that can help facilitate reaching into hard-to-reach places, the need to paint ceilings. If it weren't for the pistol extension, the ladder would be the replacement.

Hose length

Allows you to determine how far you can move away from the compressor if the spray gun has separate blocks or there is a whole painting station. When buying a long hose, take into account how far the pump with the engine can travel when it pushes the paint.

Vibration

The pistol sometimes vibrates strongly during operation, so the hand of the master will get tired. For this reason, the quality of the painting will become worse. Checking the vibration level is possible, but when comparing the operation of devices of different types. You will also be able to understand what are the properties of the overall ergonomics and weight distribution of the device.

Comparison of pneumatic and electric spray gun

Based on the above information, it can be concluded that comparing these species is difficult. Each device is good in its own way. For the home, you can use electrical appliances that are compact in size, versatile, and there is no need to impose strict requirements on them.

For production, choose a pneumatic type that has a high level of painting. Also, experts note that a pneumatic spray gun is better for the final layer of paint, and an electric one for primers.