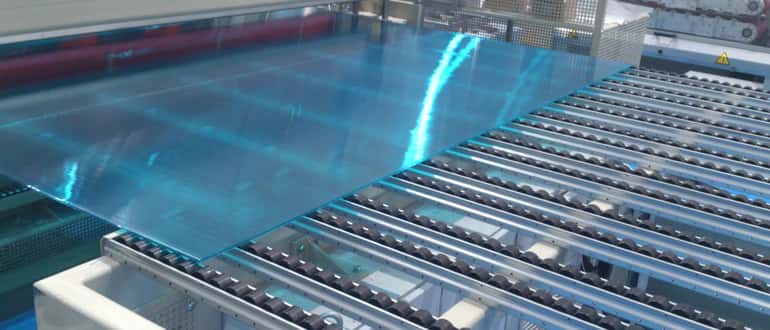

When such a building material as polycarbonate appeared on the market, many owners of large agricultural organizations and summer residents breathed a sigh of relief. This is really so, because a number of the tasks set became immediately simplified. The material, in accordance with a number of parameters, was able to surpass a number of competitors on the market. Here you can see plastic wrap, glass. At the same time, the expansion of the line led to difficulty in choosing and increasing the risks of buying low-quality products.

Today, if the task is to set up a greenhouse with your own hands, then, most often, the question arises, which polycarbonate to choose. It is necessary not to blunder, because the material can last for several years, providing normal conditions inside the structure. Going ahead, it is necessary to indicate that the purchase has a number of nuances. Acting in accordance with them, you will receive in return high durability properties of the greenhouse, while the cost of repairs will be minimal.

Content

List of polycarbonate manufacturers: which brand to give preference

Continuing the question of how to choose high-quality material, it is worth noting that today firms from Europe have become world leaders in its production. They produce premium polycarbonate. After analyzing the reviews of experts and the opinions of consumers, we have compiled a list that includes such organizations: Bayer (TM Makrolon), PolygalPlastics, PolyuItaliana and BrettMartin.

These companies really do their job conscientiously. The products meet all modern standards, and therefore they never cease to delight buyers from all over the world with excellent quality.

But it should be clarified that among Russian companies everything is also at the highest level. Polycarbonate is in no way inferior to products from the best domestic manufacturers, namely: Polyalt, SafPlast, Karboglass.

The main criteria for choosing polycarbonate

Please note that there are a number of really very important material properties that make it possible to apply it in practice successfully in the future. On the basis of them, you should make your choice. If you deviate from them, then there is a high probability that in the future you will regret your decision.

Density properties

The strength of the material, as well as its ability to withstand the harmful effects of the environment, will depend on this parameter. Be aware that over-compaction can affect weight gain as well as reduce the light transmittance of the material.

The indicator of the average density of monolithic sheets is 1.18-1.2 g / cm³, but for honeycomb panels - 0.52 - 0.82 g / cm³. In this case, the weight of the sheet will change, the thickness indicators remain at the same level. Different density values of cellular polycarbonate will be determined not only by the properties of the thickness of the internal bridges, but also by the location.

The configuration of the air channels and the density that accompanies them is presented in the following value: 0.52-0.61 g / cm³ - rectangular section, 0.62-0.77 g / cm³ - square section, 0.78-0.82 g / cm³ - hexagonal and triangular section

Weight indicator

This is an equally important criterion. Calculated for 1 square meter of plastic. The weight of the sheet, whatever the type of polycarbonate, must correspond to the product of the density of the material by the area of the panel. In particular, you need to check it when buying cellular polycarbonate. This is due to the fact that the production of 2 sheets with the same thickness and configuration of air channels may take a different amount of raw materials.

Those. the less the slab is in weight, the worse its strength properties. It will be more difficult for her to withstand wind and snow loads. Reducing the specific weight of the slab will allow you to remove the extra charge on the material, but keep in mind that the price is lower, but the quality is the same.

For the entire time of polycarbonate production, experts have calculated the standard criterion for 1 square meter, different sheet thicknesses are also taken into account.

At 4 mm - honeycomb sheet - 800 gr .; monolithic - 4800 gr.; at 6 mm: cellular - 1300 g.; monolithic - 7200 gr.; at 8 mm: cellular - 1500 g.; monolithic - 9600 gr.; at 10 mm: cellular - 1700 g.; monolithic - 12000 gr. If you want to buy high-quality polycarbonate, then equate the weight with these indicators. This is one of the important tips on how to choose a good polycarbonate.

UV protection

When exposed to ultraviolet light, the plastic loses its elastic properties and does not allow full light to pass through. Those. 2-3 years of his stay in the street will deprive the panel of the protective layer. If it is decided to use the sheets outdoors, then they must be treated in advance with protection against UV rays.

Manufacturers rely on 1 of 3 ways to protect plastics that work:

- film protection or a thin layer of a special invisible coating. This allows you to reflect part of the UV rays, and therefore the service life of the sheet is on average 15-18 years;

- volumetric protection provides for the introduction of special additives that are included in the granules of raw materials. The method is not so effective, because harmful radiation penetrates the inside of the sheet. Service life will be 10 years, but not more;

- volumetric filler + double layer of a barrier against UV rays. This method extends the service life of the material by 25-30 years. It is capable of providing complete protection to polycarbonate.

To understand what the protection of the material is, look at the special markings that polycarbonate has for the canopy. Designate it when using the first and third methods. Conclusions on the account of what degree of protection can be made by paying attention to the data indicated on the package. But keep in mind that you can only rely on their reliability if you have a certificate that confirms. You can ask the seller for it. Do not hesitate, because this will determine which polycarbonate is better for the greenhouse.

Bend radius indicator

Studying the nuances of how to choose polycarbonate for a canopy, do not forget about the bending radius indicator. It is necessary to take into account the minimum indicator for specific types of material. In view of this parameter and the thickness of the sheet, the radius will be represented by 0.6-2.8 m.

When performing installation work, these indicators should not be neglected, since excessive bending can provoke damage to the UV protection layer and the internal structure of the polymer. As a result, damage can reduce the service life of the structure itself.

Light transmission and color

These properties are really important for the material. They vary, what is the degree of illumination and the indicator of the temperature regime inside the greenhouse, in the area under the canopy. The amount of light that a material lets through will vary with transparency, color appearance, and thickness.

A bit of history

On an industrial scale, polycarbonate was first produced in the 60s of the last century.It was used in a number of areas and construction, industry. But they began to use it for greenhouses a little later. Scientists from Israel decided to do this first.

To equip a greenhouse, it is customary to use cellular polycarbonate. It is a view that is much lighter than its monolithic counterpart. It has excellent strength properties, thermal insulation characteristics. The material is presented in the form of parallel plates, which are connected by means of jumpers. They act as stiffeners, and the space between them, which is filled with air, can increase the thermal insulation properties of the material. The structure of the sheet can be 2-chambered, single-chambered, etc.

Features of the benefits of polycarbonate

We have already figured out the important features of buying material, but it will be important to notice why it is so popular with summer residents in different parts of our country. It must be admitted that he really manages to supplant film and glass with wide steps, becoming a recognized leader.

There are many reasons for this. The main advantage is that the material has excellent transparency properties, it is able to scatter the sun's rays. 92 percent of the sun's rays pass through the colorless material, and this will have a positive effect on the plants that need to be grown in the greenhouse. If the material has a special protective film, then crops will not be affected by hard UV radiation. Weight indicators are not high, less than that of glass. Those. the frame of the greenhouse will not suffer from serious stress.

Immediately it is necessary to indicate that polycarbonate is flexible, plastic. During installation, you can create arched greenhouses. The mechanical strength indicators are also decent. From the impact, the material will not tear like a film, and it will not break into fragments like glass. The thicker the polycarbonate, the more difficult it is to affect its integrity.

Varieties of polycarbonate

Today, experts identify 3 types of polycarbonate. It is cast (monolithic), cellular (honeycomb) and profiled. Due to the type of material and features of the technical plan, which include the density of the sheet, its thickness, the number of jumpers and their location in cellular polycarbonate, it is customary to use plastic for a number of certain works.

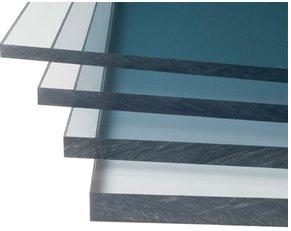

Monolithic polycarbonate

A polymeric sheet of a solid base, which has a thickness of 1-12 mm. He has no internal voids. From the outside, it is presented in the form of plexiglass, i.e. acrylic glass. Manufacturers are busy producing panels with a thickness of up to 20 mm.

Each leaf is presented in a transparent, colorless and translucent shade. There are color options that have a low degree of light transmission.

Indicators of density and viscosity of polycarbonate, which is obtained by the injection method, can increase the properties of resistance to mechanical loads. At the same time, the indicators of the impact strength of the polymer will be 1000 kJ / m².

Continuing to study the topic of how to choose polycarbonate, it is worth noting that this indicator is really important. The multiplicity of the excess in comparison with other popular materials that are used in the construction of structures of a translucent base will be equal to the following measurements: 60 - plexiglass, 150 - polystyrene, 200 - silicate glass.

Panels based on monolithic polycarbonate are able to withstand bad weather. They will not be afraid of a strong gust of wind, snowfalls or hail. The surface tends to crack from impacts of a strong nature, and dangerous sharp fragments can form that can injure a person. But this case is not appropriate.

If necessary, the panels can be bent, the shape will be arched. The bend radius will largely depend on how thick the polycarbonate is. The thinner the sheet, the smaller its radius.

Monolithic polycarbonate has high frost resistance properties. If there are no mechanical loads, then the material is able to withstand a temperature regime of -50 degrees.If shock loading is also observed, then the temperature will be -40 degrees.

Speaking about heat resistance indicators, it is worth noting that in some cases the products of brands are equal to +120 degrees, but there are also options up to +150 degrees. On the basis of polymer polycarbonate, constructions with translucent properties are made, screens with noise protection and shock-resistant properties, which are used in interior design.

The advantages are that the material has high impact resistance properties, as well as the ability to transmit a high amount of sunlight, sometimes 90 percent. The weight is small, due to this, the work of the installation plan, as well as transportation, are not accompanied by problems.

The handling is not complicated. Sheets can be easily cut, sawed, drilled. As already mentioned, shock resistance is another useful material property. The quality of sound insulation and thermal insulation is also up to the mark.

Let us denote the fact that the material is not afraid of fire. It only melts, is able to block UV radiation due to a special protective layer. It is completely safe for humans to use. Moreover, the market is represented by a wide variety of color shades, while the color does not fade over time.

As you can see, this polymer polycarbonate has a lot of advantages. But this does not mean that he is perfect. The downside is that there are options that scratch easily. Although there is success in this direction. Today the world's leading manufacturers have been able to develop the technology of monolithic polycarbonate, which has an anti-abrasive coating. It is able to protect the surface of the material from scratches and other types of damage.

Stains may remain on the surface due to the ingress of technical solvents and various acids. The degree of thermal expansion is significant and must be taken into account for the installation of the coating.

As for the cost, there is also a minus. The price is high, and therefore the decision to equip the building with polymer polycarbonate will cost you a pretty penny.

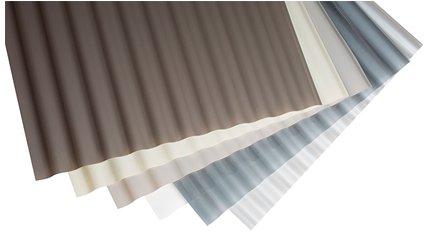

Profiled polycarbonate

The material belongs to the load-bearing, structural. It has the properties of decorative and translucent fencing. It is very common in the private sector in the case of the construction of fences, greenhouses, and is also used very often as a material for the roof. It should be attributed to the types of molded polycarbonate.

Sheets with a trapezoidal surface or wavy are characterized by a small thickness. It varies in size 0.8-1.5 mm. The sheets are lightweight, they are translucent or transparent. Suitable for successful roofing and can withstand a load of about 320 kg per square meter. As a roofing material, profile polycarbonate can replace ondulin and corrugated board.

The material is divided in accordance with the shape and size of the wave, the color scheme, the degree of transparency. It can be colored or colorless. If these are translucent panel solutions, then they, most often, are smoky or matte, but opaque ones are bright.

Among the advantages is the fact that the material has the properties of monolithic polycarbonate, and its stiffening ribs are many times capable of increasing reliability indicators, while the sheet is small in thickness.

Strength is easily comparable to that of metal-type corrugated board. In this case, the weight of the material will be several times less. Profile polycarbonate is resistant to the process of corrosion formation, and it transmits light up to 86 percent. Ease of installation and flexibility of profiles is appropriate for use in arched structures. It is worth noting that all this allows it to retain its color for a long time. The sound insulation values are high enough to prevent dripping sounds when it rains. Quietness is a really important parameter for many buyers.

But the material is not deprived of cons. First of all, let us designate that it costs quite high at a price.As a fastener, special thermal washers can be used, which ensure that the sheet is well fixed in case of temperature changes and changes in humidity.

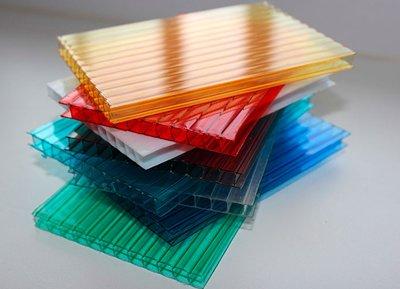

Cellular polycarbonate

This type of material has gained high popularity among the builders of greenhouses and greenhouses. It has a complex structure than other types. Consists of plastic layers that have jumpers. They provide the rigidity of the material itself. The voids that can form in this case can increase the degree of thermal insulation and sound insulation of polycarbonate. As for the thickness indicators, this parameter varies in the size of 4-50 mm.

Today it has several varieties. In the case of connecting 2 sheets, it is considered to be a single-chamber material, 3 - two-chamber, 5 - four-chamber, 7 - six-chamber.

Webs or stiffeners can be located perpendicular to the surface of the sheet and at an angle of 45 degrees. There may be different distances between them. 5.7 mm - 25 mm. Those. everything changes to the kind of layers of material.

There are a number of manufacturers that specialize in the production of cellular polycarbonate, its honeycomb can be filled with airgel. It has high impact resistance properties, and the degree of thermal insulation is located so that it can reduce heat losses much better than 3-chamber double-glazed windows, supplemented with argon.

The advantages are that the material has excellent thermal insulation properties, it is able to uniformly diffuse the light flux, which has a beneficial effect on plant growth. The frost resistance indicators are high. As for the price, it is affordable in relation to other plastics. The weight relative to the glass is not great. In practice, it is distinguished by its safe properties, and it pleases with its high impact strength.

As for the disadvantages, they are that during installation you need to take care of ensuring reliable fastening of the panels, since the windage of the material is large. Otherwise, wind gusts will be so strong that they can disrupt the integrity of the structure.

During installation, you can use a special kind of fasteners. In this case, the material has a significant degree of thermal expansion. Yes, and before abrasives and solvents, it has very unstable performance.